ROBOT TECHNOLOGY JAPAN 2024

After Report

ROBOT TECHNOLOGY JAPAN 2024 was held at Aichi Sky Expo (Aichi International Convention & Exhibition Center) in Nagoya, Japan, from July 4 (Thursday) to July 6 (Saturday), 2024.

This is one of the biggest B to B exhibitions in Japan, hosted by News Digest Publishing Co., Ltd. and held in “Central Japan,” an industrial area with a cluster of manufacturers.

In this exhibition, the scope of the exhibition is specialized in “industrial robots” used in manufacturing sites and logistics bases, “devices and equipment” with industrial robots integrated in them, and “automation systems” using like AGVs (Automatic Guided Vehicles)/AMRs (Autonomous Mobile Robots).

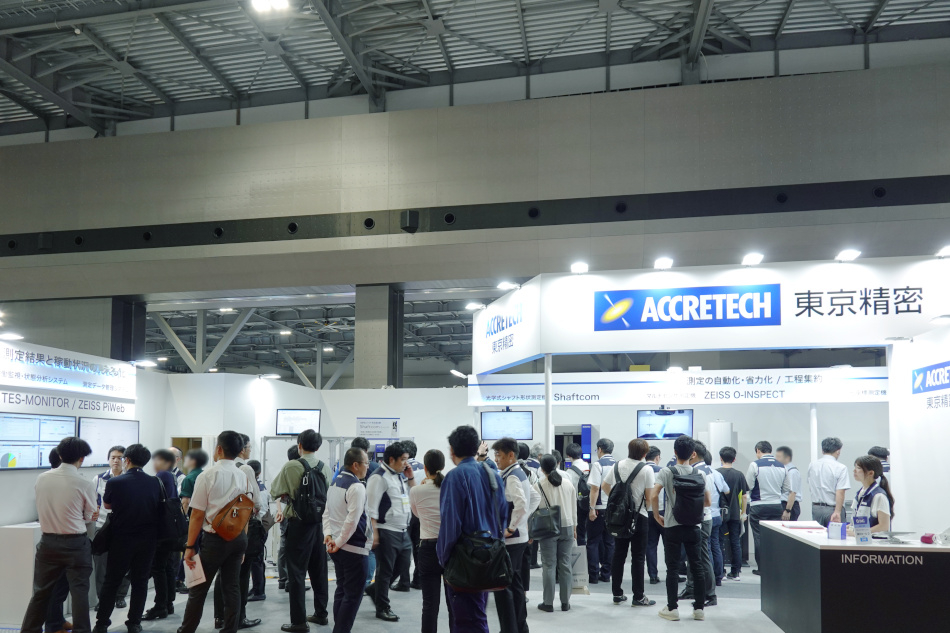

In our booth, we divided the solutions into two categories: “Automation/Labor-saving/Concentrating Process of Measurement” solution and “Visualization of Measurement Results and Operation Status” solution. For the first solution, we had Optical Shaft Measuring System [Shaftcom], Multi-sensor Measuring Machine [ZEISS O-INSPECT], and Coordinate Measuring Machine [ZEISS DuraMax+BasicPackage] on display. For the other one, we had a monitor exhibition of the [TES-MONITOR] and [ZEISS PiWeb]. In addition, we gave a presentation at the entrance of the booth in response to our customers’ requests. After that, visitors were able to see the products that they were interested in.

The booth was so crowded with many visitors, with more than 200 visitors on the first day and the second day of the exhibition. Although the turnout decreased on the final day due to a holiday, we were able to attract a different range of visitors to our booth than on the first two days, including students and families.

①

Automated/Labor-saving Measurement Solution DuraMax + Collaborative

This is a solution for those who are considering the introduction of robots for the first time for automation in the measurement process.

②

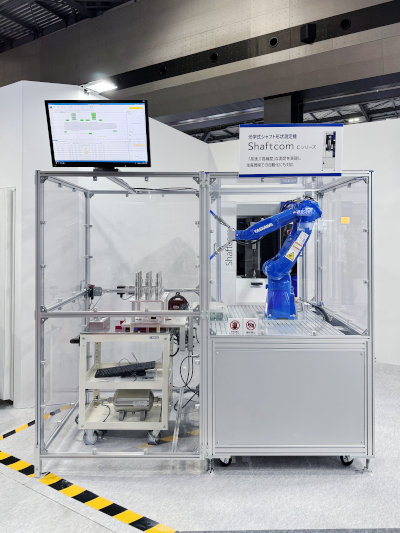

Automated/Labor-saving Measurement Solution Shaftcom C series + Industrial Robot

The Shaftcom C series optical shaft measuring machine, which enables high-speed, high-precision measurement, is combined with Tokyo Seimitsu's automated/labor-saving measurement solutions.

③

Optical shaft measuring system Shaftcom C series

The Shaftcom C series is an optical shaft measuring system that realizes "high-speed" and "high-accuracy" measurement and can be automated at the production site.

It is possible to evaluate dimensional and geometric tolerances of shaft-shaped workpieces in a short time.

④

Multi-sensor measuring machine ZEISS O-INSPECT

The ZEISS O-INSPECT is an all-in-one measuring machine with contact and non-contact sensors that combines the proven measuring technology of the ZEISS industrial measuring machine division with the outstanding optical technology of the microscope division.

Tokyo Seimitsu provides customer-friendly services with ONE STOP SOLUTION. The greatest feature of our automation/labor-saving measurement solutions is that ACCRETECH group oversees the entire service package, from listening to customers’ requests, planning, design, quotation, and system introduction, to after-sales support.

Furthermore, we do not propose our planning, design, and quotation services for the measuring instrument alone but rather the entire system integrating all essential elements, such as robots, AGVs, jigs, and programs.

It is possible for customers to consider automation/labor-saving system without any hassle prior to installation, so we can provide a comprehensive service, including communication with manufacturers of robots and other transfer equipment and SIer (System Integrators), as well as fabrication of necessary jigs.

Date

2024-7-4(Thu) to 2024-7-6(Sat)

Host Area

Japan

Venue

Aichi International Convention & Exhibition Center (Aichi Sky Expo)

Official website