GOM Volume Inspect Pro

GOM Volume Inspect Pro is measurement and analysis software for use with CT. The software provides all the functions of the CT process, from the acquisition and restructuring of scan data, to data evaluation and report-writing. The software can accurately evaluate shapes, nests, voids, internal structures, assembly states, and so on.

Features

Scanning, restructuring, and surface geometries can all be completed in GOM Volume Inspect Pro

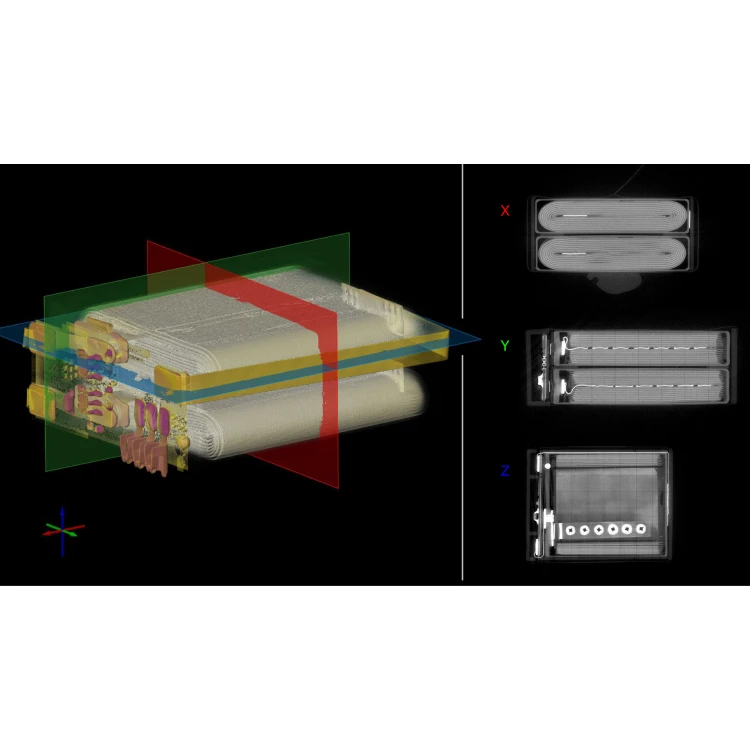

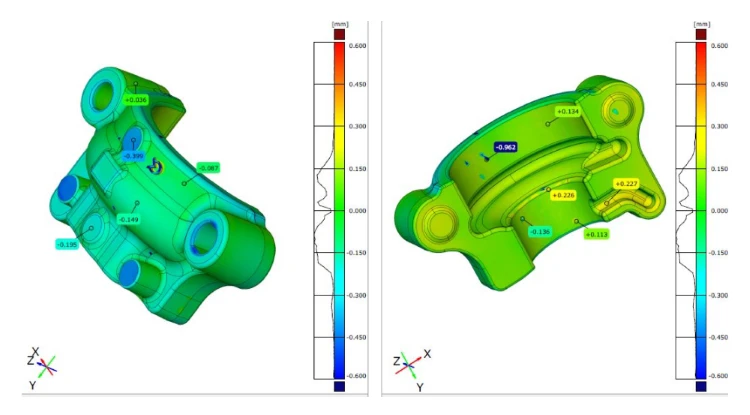

GOM Volume Inspect Pro implements surface geometries from the acquired CT scan data, and can be easily operated to create alignment with CAD data and a coordinate system. After running a variety of evaluations such as the color map display of the deviations with the CAD data, the measurement of geometric tolerance, defect analysis, and thickness analysis, the software can seamlessly create a report with one mouse click. Using the “Volume Detail View” feature, GOM Volume Inspect Pro displays the cross-section of a volume simultaneously from various angles, and can customize the transparency of the display and the color design.

In addition, when GOM Volume Inspect Pro applies measurements and analysis conducted previously to scan data of another workpiece of identical shape, the user can re-evaluate the newly scanned data by simply dragging and dropping. The software performs all the alignments, measurements, and analyses automatically. It can calculate and display the average and standard deviation of data of several parts, and the process capability index, etc., and it can easily perform trend management by workpiece and comparison of measurement results.

Maximize the measurement efficiency with batch scanning

The software uses the “Volume Separation” feature to scan several parts in one batch, and to extract the parts data from the scanning range one set at a time. In this way, it can easily evaluate individual parts and compare respective parts. If this feature is used in the ZEISS METROTOM 1 which is equipped with X-ray tubes that have the greatest output within the ZEISS METROTOM series, it can perform measurements efficiently and flexibly. For example, it can scan 30 resin molded products simultaneously in one cycle of 11 minutes and evaluate the individual workpieces afterward using the “Volume Separation” feature.

Comprehensive report display using video

Using the GOM Volume Inspect Pro does not require expert knowledge of volume data analysis or report creation. Not only can the user virtually move each layer of a component, but they can record the data while they are being moved. In this way, the user can present the video data as well when sharing analysis results with another person, and can make a report that is easy to understand. The reporting module enables documents to be printed out and PDFs to be output with attached video data, so that anyone can create a report easily.