Features

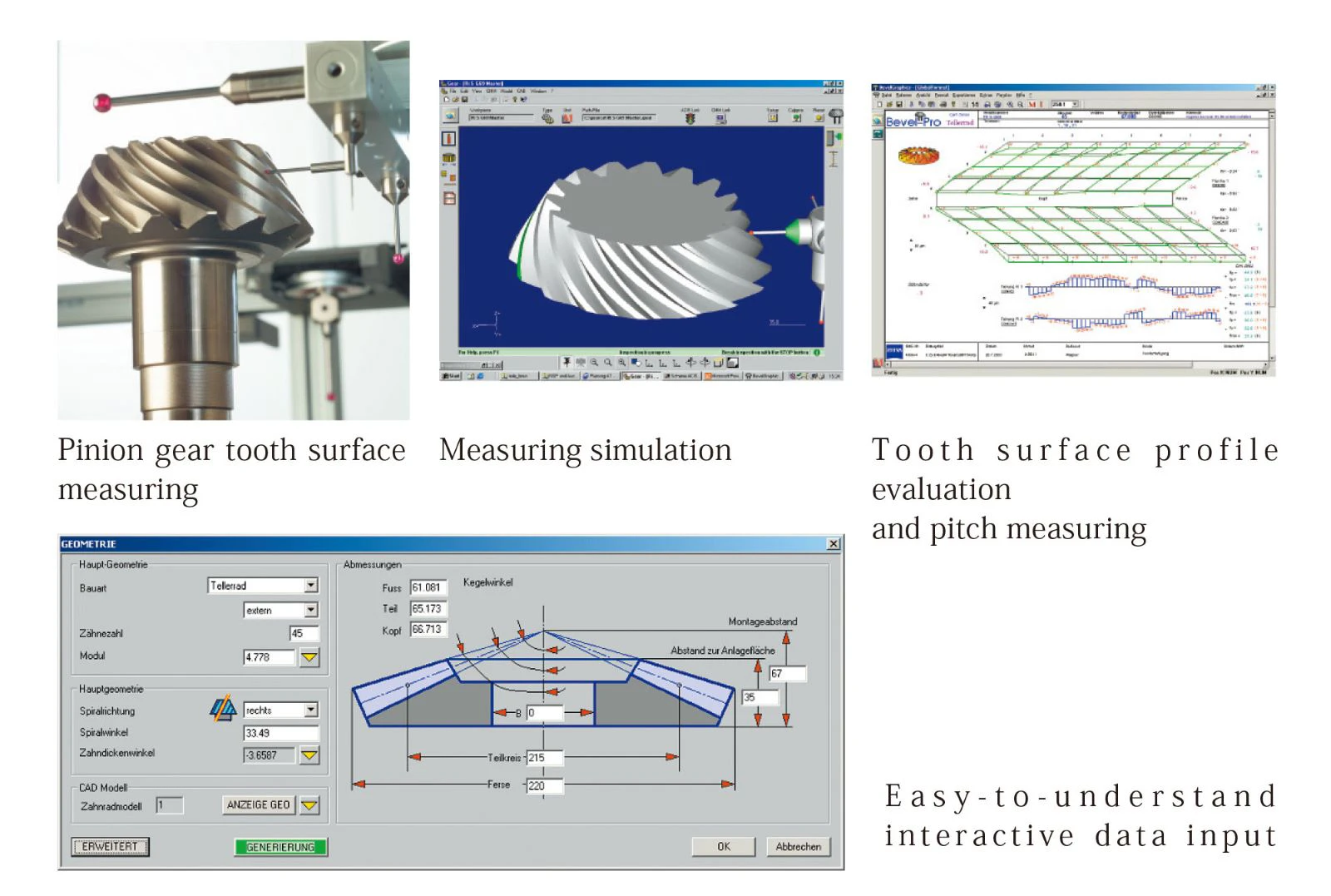

GEAR PRO bevel: Bevel Gear Measuring Program For Hypoid Gear Measuring (option)

This program performs tooth surface profile measuring and evaluation based on bevel gear and hypoid gear reference values.

Tooth surface reference values can be imported using DCOM (option) or generated by measuring a master gear.

<Evaluation Items>

· Measurement result output to the screen or a printer

· Tooth surface profile evaluation

Measurement results can be output in table form and topographic form.

Comparison evaluation with tooth surface profile reference values generated using a master gear, etc.

Comparison evaluation with manually input reference values

Comparison evaluation based on a Gleason gear reference value file

· Pitch/tooth space runout evaluation

Single pitch, pitch, adjacent pitch, tooth space runout

Gleason interface is required in order to perform comparison evaluation based on a Gleason gear reference value file. (Option)

Gleason interface can be used to link with the G-AGE program (available from Gleason Asia) through a bevel gear measuring program. Machine setting corrections can be calculated for a Gleason gear cutter.

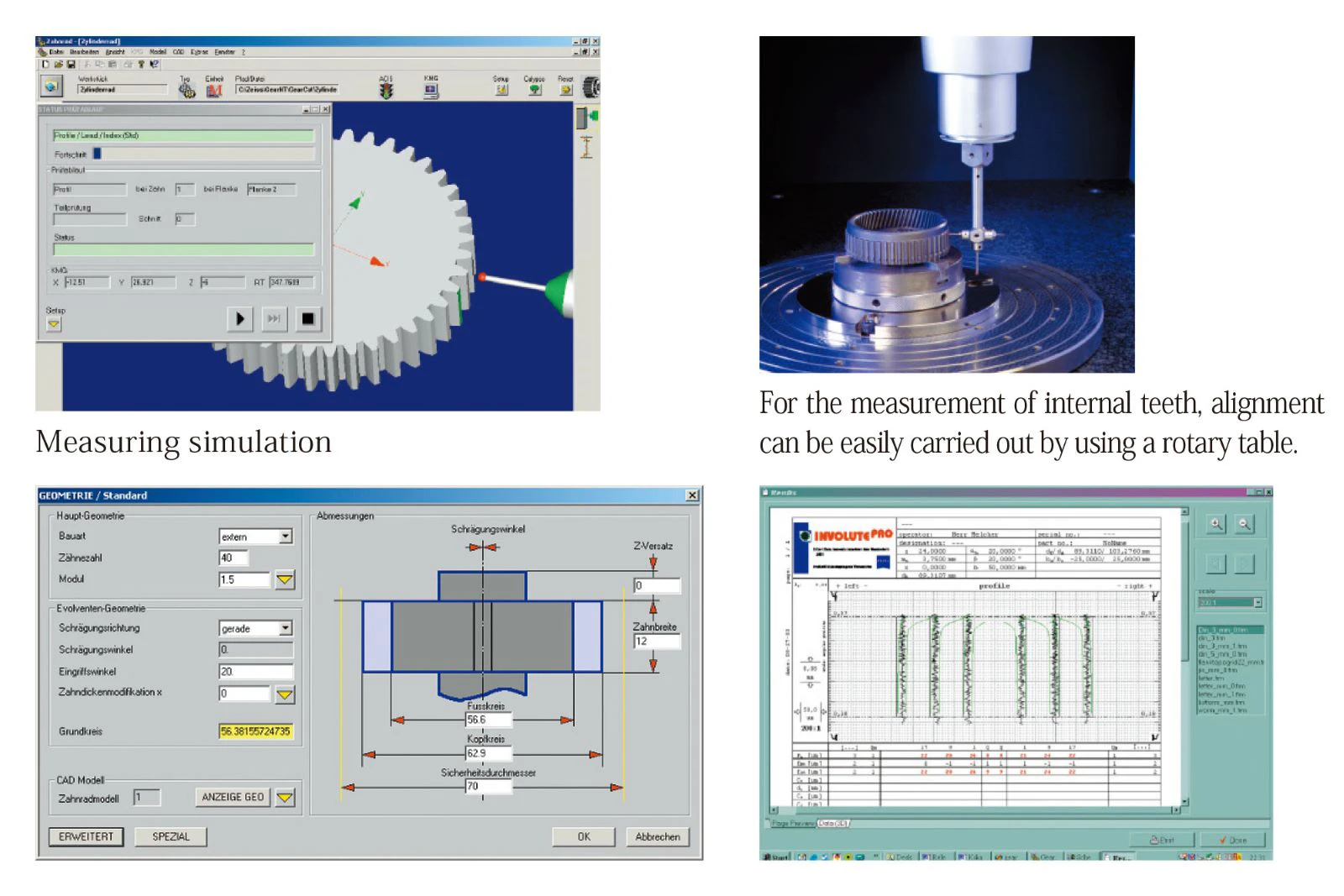

GEAR PRO involute: Cylindrical Gear Measuring Program For Spur and Helical Gear Measuring (internal and external tooth) (option)

Automatic measurement can be performed simply by inputting gear data.

Operation is performed using an interactive system.

<Operation Methods>

· CNC full automatic measurement

· Measuring item selection (tooth profile/tooth trace/pitch)

· Tooth profile, tooth trace measuring tooth selection (1 to 4 teeth/all teeth)

· Measuring tooth surface selection (right, left, both surfaces)

<Evaluation Items>

· Tooth trace & profile

Total error, Profile variation, Angle variation, Crowning

· Pitch

Cumulative pitch error, single pitch error, adjacent pitch error

· Tooth space runout

<Topography evaluation (option)>

<Measuring simulation execution (offline)>