XYANA smart®

Making coordinate measurement more "intuitive"!

Innovative software for easy, effortless measurement without hesitation

Features

XYANA smart® supports CNC measurement!

"We want to make CNC measurement easier." "We want to create measurement programs effortlessly even for prototypes and small-scale production items without CAD data"

--In response to such customer feedback, new functions have been added to the manual-type (manual/joystick type) coordinate measuring machine software XYANA smart®.

It has been reborn as new software that also supports CNC measurement.

Features of CNC measurement with XYANA smart®

Teaching is extremely simple and easy

The movement path during teaching can be directly registered as the path for executing the measurement program

Measurement programs can be created efficiently and safely with the new "midpoint auto input function"

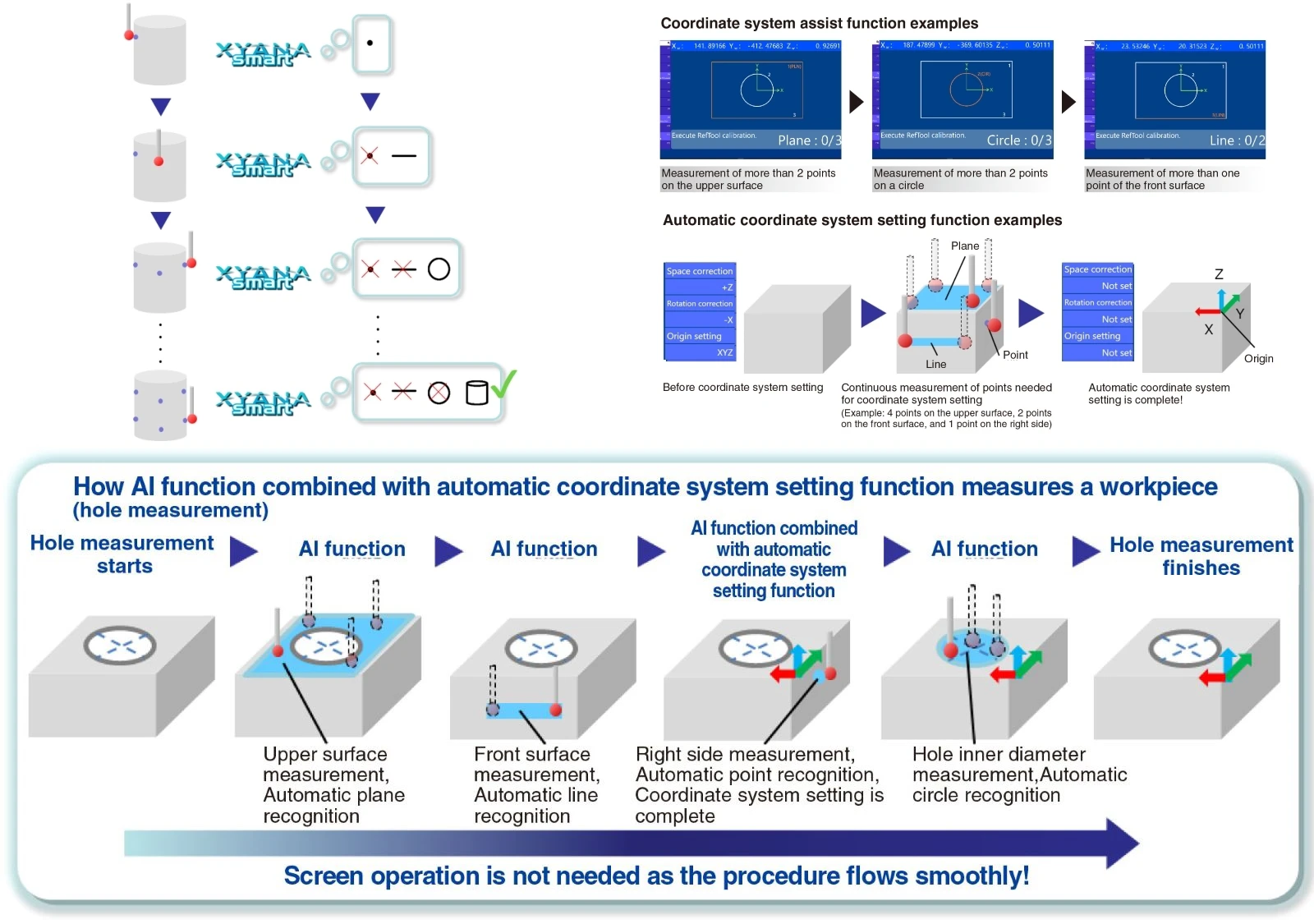

With the "AI function," geometric features can be automatically judged, allowing for smooth teaching without specifying the geometric features to be measured in advance

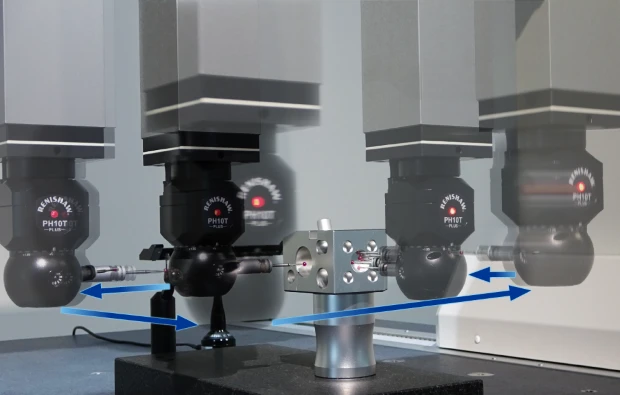

Automatic exchange paths for styli/modules using a changer rack can be set easily

Preparations before executing CNC measurement can be made quickly and without hesitation

The "coordinate system assist function" and the "automatic coordinate system setting function" enable swift coordinate system setting regardless of the user's experience level

Collision avoidance calibration semi-automates calibration tasks safely

Once the coordinate system setting and calibration are completed, all that’s left is to execute the pre-made measurement program

CNC measurement programs that conform to DMIS and are easy to edit

Coding of measurement programs in XYANA smart® conforms to the interface standard for dimensional measurement machines, ISO 22093:2011, known as DMIS (Dimensional Measurement Interface Standard). This enables collaboration* with external software that can import and export DMIS-compliant programs.

Moreover, a multi-functional program editor with excellent visibility is provided as standard, making it easy to edit measurement programs.

* There may be cases where collaboration is not possible or where complete replication of operations is not achievable. If you are considering, please consult our sales office in advance.

Intuitive UI supporting both touch input and key-in

Items such as functions, conditions, and measurement results are shown in large size for easy-to-see and easy-to-touch operation. Preparation, measurement and evaluation can be performed as a flow with simple procedures and unified operation from top to bottom and from left to right.

Both touch and keyboard input can be performed quickly and efficiently by using shortcut keys and codes assigned to items.

No hesitation in operation shortens the duration of preparation and measurement

AI function for automatic geometric feature judgement

This function automatically judges geometric features (points, lines, circles, spheres, planes, cylinders, cones, etc.)

while conducting measurement by considering the number of measurement points, directions, etc.

Measurement can be performed efficiently without specifying a geometric feature before each measurement.

Coordinate system assist/automatic setting functions to make coordinate system setting easier

While coordinate system assist function supports inexperienced operators in coordinate system setting,

automatic coordinate system setting function helps experienced operators who can estimate probing points needed for coordinate system setting and makes setting work more efficient.

Voice guidance function for effi cient and safe measurement

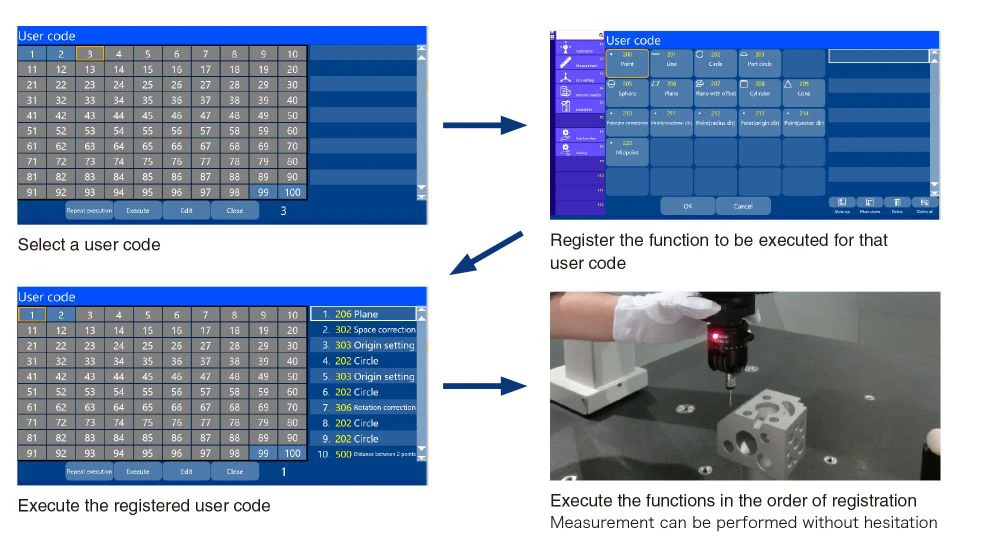

User code function allowing the operator to register preparation, measurement, and evaluation procedures freely

Up to 100 XYANA smart® function procedures can be registered as user codes. Functions are automatically performed according to the set procedure by calling a user code. Efficient measurement can be performed without searching the function to be executed or manually switching the screen.

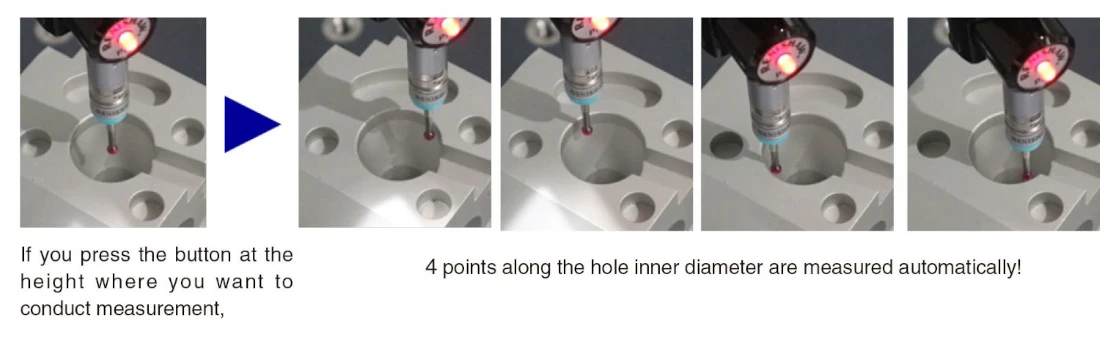

Automatic inner hole diameter measurement function for easy measurement with pressing a button

Unique auto probing function equipped in the joystick machine XYZAX mju NEX J can be further upgraded.

This function can perform automatic probing of 4 points along the hole inner diameter by simply pressing a button, making measurement simpler and more efficient.