ZRE (ZEISS Reverse Engineering)

Software that can intuitively conduct reverse engineering and has an innovative, efficient and quantitative injection molding tool correction

Features

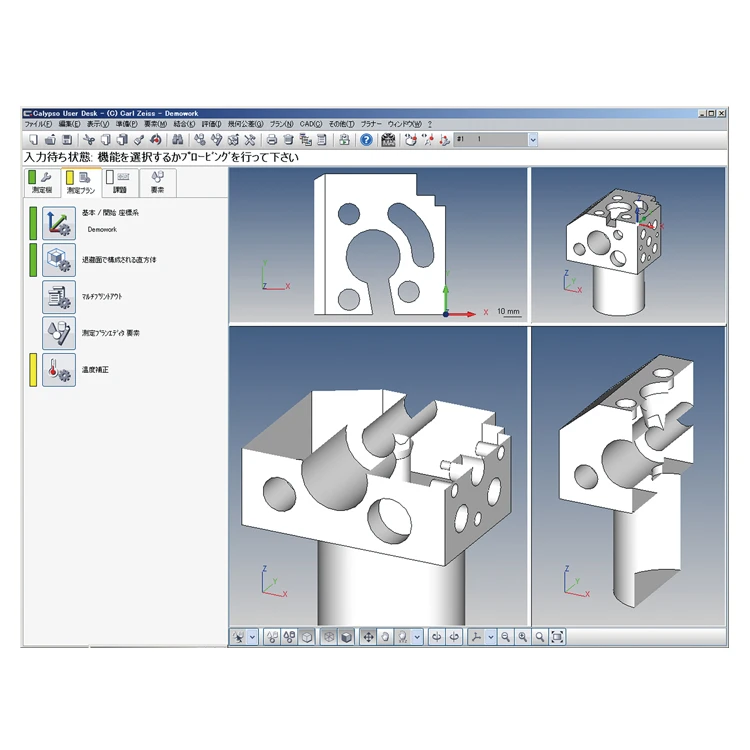

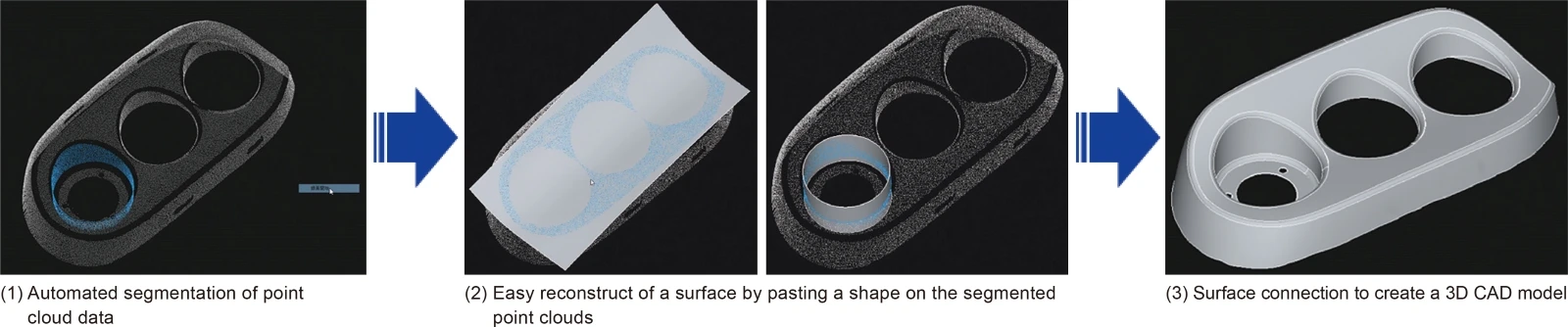

Reverse engineering with an intuitive procedure

ZRE can create 3D CAD models from measured point cloud data with a simple procedure. Unlike conventional software, it does not require pasting of triangle meshes; instead, it creates a surface directly from point cloud data.

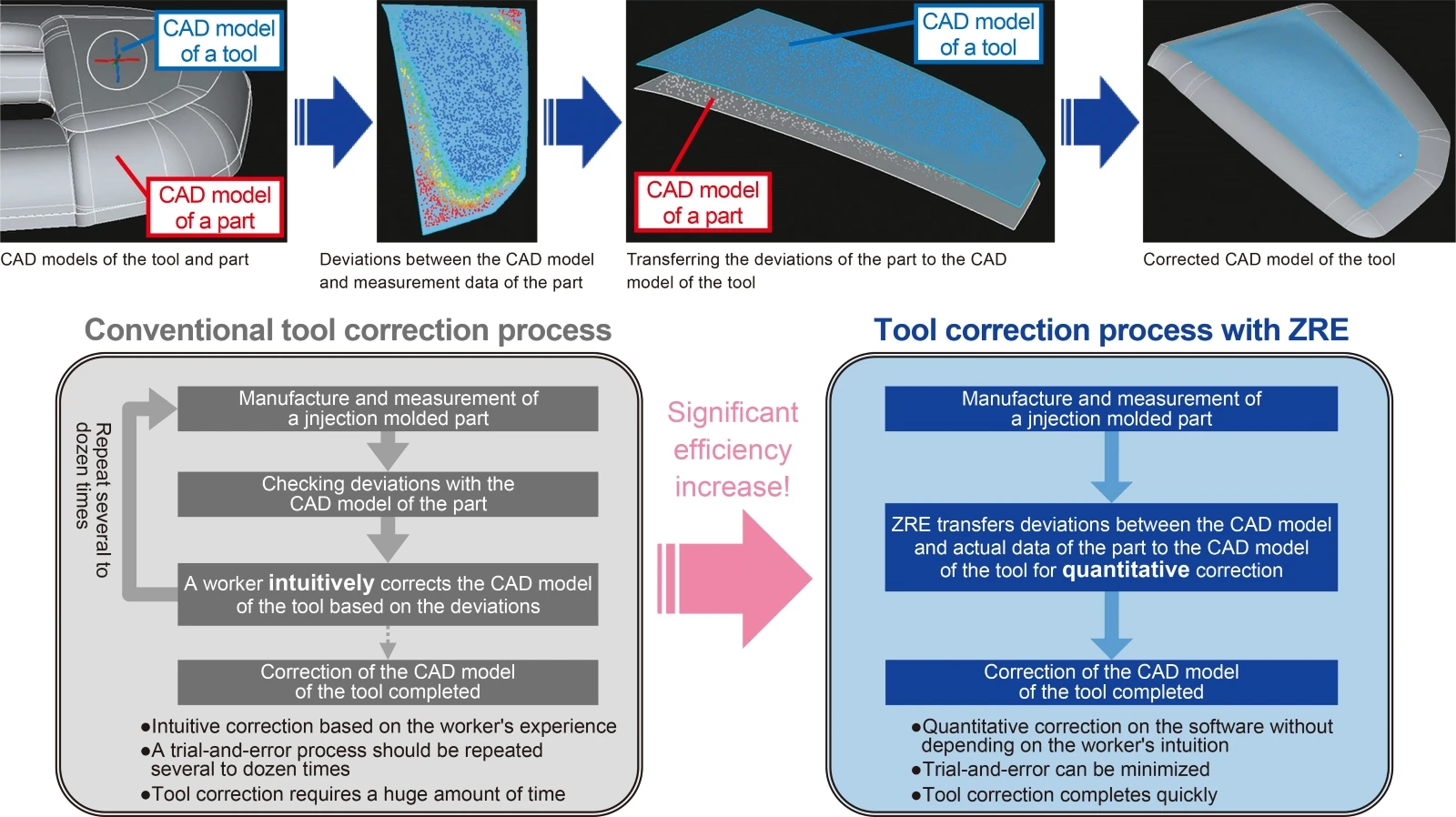

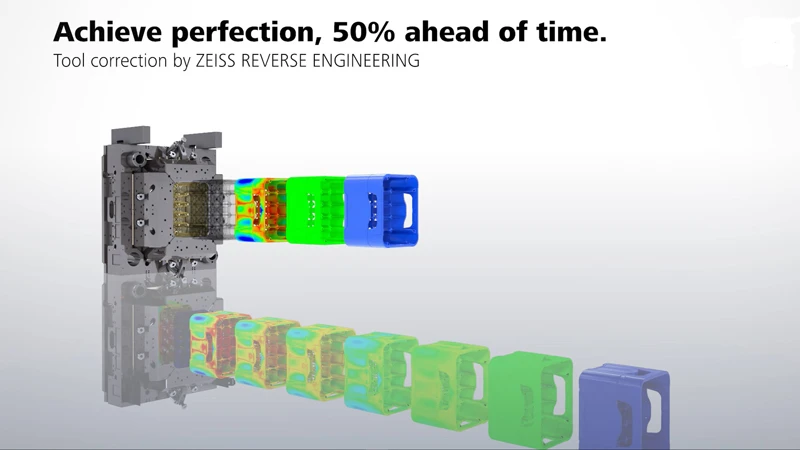

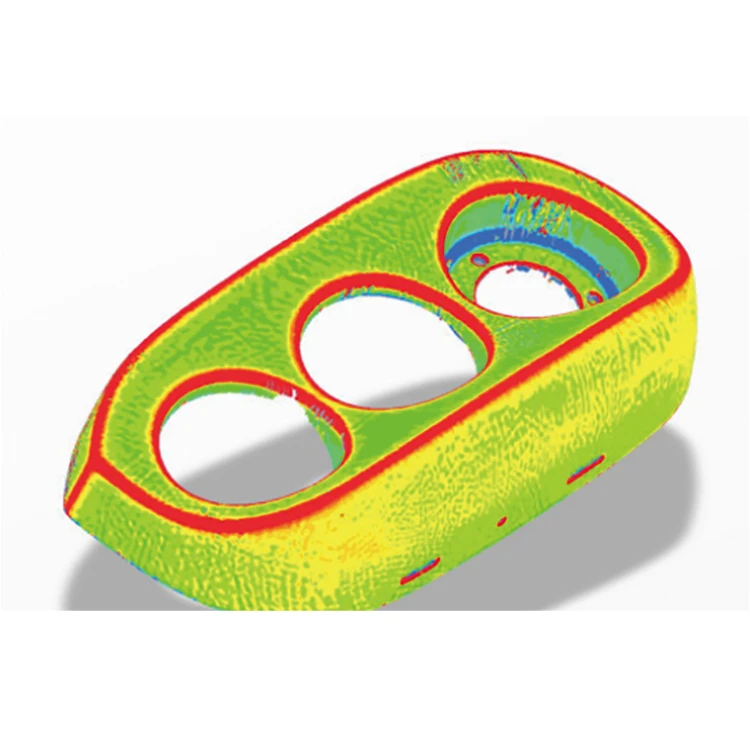

Tool correction” innovative and quantitative correction CAD models of injection molding tools (optional)

Classical method of tool correction is performed by workers using intuition based on measurement data of an actural injection molded part. This new method transfers deviations between the 3D CAD model and actual data of the part and quantifies the amount of tool correction. Thus, the trial-and-error process of measuring a part, correcting the CAD model of the tool, remanufacturing and measuring the part, and recorrecting the CAD model of the tool is minimized. Tool correction can be performed efficiently without requiring experienced workers.