Crystal Optics Inc. pursues integrated production in ultra-precision polishing, catering to everything from polishing of optical crystal, to the aircraft industry. As a customer of ACCRETECH products supporting high-accuracy product manufacturing, we spoke to Crystal Optics about their impressions and requests relating to our products.

Supporting everything from optical crystal to the aircraft industry leveraging ultra-precision polishing prowess

episode 04 What are your thoughts on overseas expansion? episode 05 Do you have any further expectations of measuring equipment and ACCRETECH? epilogue Tokyo Seimitsu’s thoughts after speaking

Crystal Optics Inc.

Shigeru KIRINO, President

Founded in 1985, Crystal Optics Inc. is a precision polishing company leveraging its advanced technological capabilities in its challenge to achieve ultra-precision polishing for everything from new materials to general materials. Today, Crystal Optics supports Japan’s leading industries through catering to a diversity of fields, including environmental conservation, aerospace, analysis, semiconductor, liquid crystal, and optics, while promoting integrated production comprising of processing, ultra-precision cutting, grinding, polishing, and measurement.

Head office & plant: 3-4-25, Imakatata, Otsu city, Shiga prefecture 520-0241, Japan

Kyoto plant: 47Kyotosinkouetsumura, Sonobecho Uriuno, Nantan-shi, Kyoto 622-0021, Japan

What do you mainly focus on when you consider which measurement equipment to introduce?

Kirino

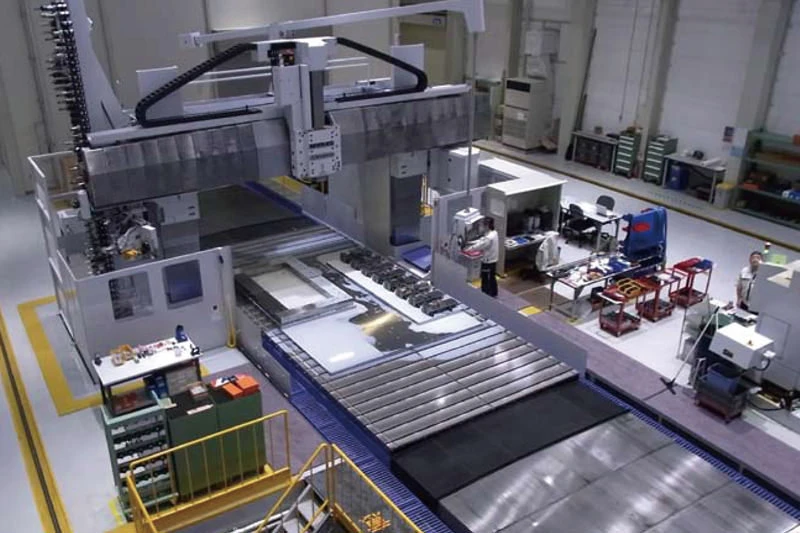

Crystal Optics has many of ACCRETECH’s measuring machines in our plants, and our criteria when choosing these machines is not only their merits/demerits but also the interpersonal connection. This is something we really prioritize. In that sense, through interacting with ACCRETECH to date, we have forged a solid relationship of trust, and have a strong impression of it as a sincere company. We had high expectations of the Carl Zeiss MMZ-G we installed recently because it was one of only three in the world, however, our decision was definitely swayed not only by that fact but because it was a trustworthy brand presented by both ACCRETECH and Carl Zeiss.

Please tell us your thoughts on Crystal Optics’ monozukuri and measurement

Kirino

In the world of ultra-precision polishing, accuracy takes priority over all. Even if a product is extremely beautiful, sometimes it may be problematic accuracy-wise at a micron level, or sometimes even at a nano level. Considering this crucial point, Crystal Optic pays close attention not only to measurement in the final process but also in the middle of manufacturing processes to secure sufficient product accuracy. The fact that we engage in integrated production means that we are probably at a disadvantage due to the fact that equipment investment is costly、however, we made this decision because we believed that if we received products from a primary processing company, then performed secondary and tertiary processing, it would create not only lead-time and cost issues but also accuracy issues. That is why we are just as thorough about which inspection device to introduce to our operations as we are about which production equipment to introduce.

Please tell us your impressions of using the new equipment.

Kirino

The biggest thing I noticed after introducing the Carl Zeiss MMZ-G to our operations is the difference in the level of trust our customers place in us. I truly get the sense that customers feel they can trust us because we have that CMM. Also, I think we were able to enter the aircraft industry, which has so much growth potential, thanks to owning a large CMM like MMZ-G. Based on our concept of “Looking ahead to the future,” we have had success to date by being that one step ahead of world trends, such as liquid crystal and semiconductors. On the other hand, we’ve also experienced cases where we couldn’t achieve the necessary accuracy no matter how hard we tried. Even in such cases, as long as we can show customers the measured data and provide a detailed report on the issues, such as “This part is dented,” or “This part is off-center,” and the customer can evaluate the data even if the required accuracy cannot be obtained, then the problem can be dealt with when the final product is made. I believe an advantage of owning precision measuring equipment is that, rather than delivering a product to a customer which just barely passes the accuracy requirements, we can also present details on error in the form of data. Now, we are engaging in activities to obtain the necessary certification as a plant manufacturing aerospace equipment,, which we plan to complete by next spring. Through this, we believe Crystal Optics will be able to offer monozukuri of even higher added value.

What are your thoughts on overseas expansion?

Kirino

Moving forward, I think we will see a shift toward added-value products being manufactured in Japan and standard products manufactured overseas. In light of this, I tell our young employees “Don’t be a craftsperson, be an excellent engineer,” so that they may manufacture high-quality products. In many cases, a craftsperson has outstanding skills in regards to one specific area, however is unskilled in all other areas. That’s why I think it’s important to be able to measure what you create yourself on your own and improve skill while evaluating the current status. As the next step in our journey, let’s aim for an even higher level. By repeating this cycle, I believe that we can improve skill and uphold Japanese monozukuri.

Do you have any further expectations of measuring equipment and ACCRETECH?

Kirino

Our products are polished. As such, we don’t want to scratch them even a little. That’s why we’d love to have a non-contact type measuring device capable of measuring even spherical surfaces at high accuracy. Also, it would be handy to have a simple, portable measuring device able to perform measurements inside our machines at high accuracy. We are satisfied with ACCRETECH’s service and maintenance, but if we could wish for more, we’d be thankful if you had a bit stronger presence in the Kansai region.

Tokyo Seimitsu’s thoughts after speaking

After speaking with Crystal Optics, we renewed our sense of the importance of inspections in supporting accuracy. We were surprised that Crystal Optics covers such a broad range of products, from optical crystal to aerospace, however were intrigued to hear that the fundamental technology is the same.