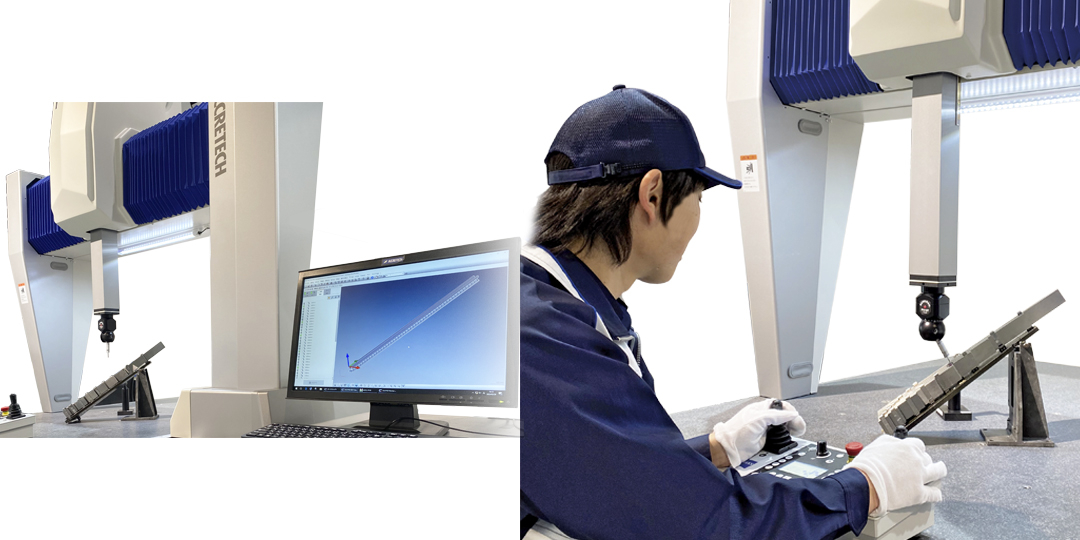

Inspection Services

Periodic inspections and calibration help maintain quality of measuring instruments.

Measurement results are one way of determining whether or not a product is satisfactory, but evaluations of finished products can be affected if the actual measuring instruments are in poor condition.

Measuring instruments need to be maintained at a level of precision that is called for daily evaluations.

With customers working on ISO-compliant projects, there has been an increase in recent years where inspections also need to be factored into operations.

Service plans

Multiple inspection service plans are available to suit customer requirements.

Meets customer's ISO requirements

Maintenance

Measurement instrument accuracy

Main service

Maintenance

Adjustment (optimization)

Compensation

Stylus confirmation

X, Y, Z length measurements

4 spatial direction measurement

Parallelism

Issue calibration documentation

Issued documents

Manufacturer calibration certificates

Inspection reports (after inspection and adjustment*1)

Traceability charts

Maintenance

Specific calibration requirements

Main service

Maintenance

Adjustment (optimization)

Compensation

Stylus confirmation

X, Y, Z length measurements

4 spatial direction measurement

Parallelism

Issue JCSS calibration documentation

Issued documents

JCSS calibration certificates

Calibration results*1

Customer internal management

Verify measurement instrument accuracy

Main service

Verify measurement instrument basic properties

X, Y, Z length measurements

2 spatial direction measurements

Interim check report

Condition report

Issued documents

Interim check report

Service details vary depending on product.

1: An additional service is available for issuing inspection results prior to inspection and calibration, as well as JCSS calibration certificates before and after inspection and calibration, so please inquire if required

Summary

Traceability at Tosei Engineering

Inspection and calibration of measuring instruments

Calibrating measuring instruments "at specified intervals, or prior to use" is a requirement under the ISO 9001 standard for quality management systems, but establishing an unbroken chain of calibrations (traceability) against international or national measurement standards is also required.

The validity of measurement results can only be trusted when traceability is established.

In addition to ISO 9001, there are an increasing number of public procurement requirements and various other industry standards that require results to be "traceable to international or national measurement standards."

Tosei Engineering has developed a comprehensive system capable of meeting such needs that customers may have.

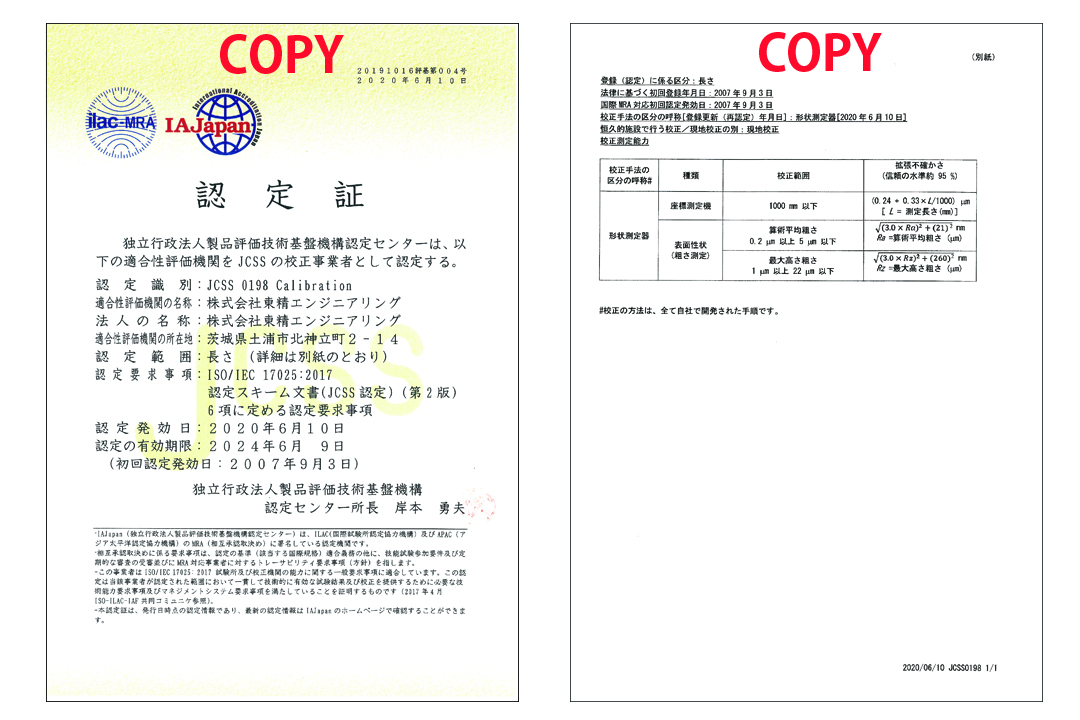

JCSS calibration

Both Tokyo Seimitsu and Tosei Engineering are certified as accredited calibration laboratories in the Length category under the traceability system of the Measurement Act. Tosei Engineering's JCSS calibration certificate is recognized and valid globally, and we are a JCSS accredited laboratory and accredited as a calibration laboratory that meets MRA (Mutual Recognition Arrangements) requirements (JCSS 0198) for coordinate measuring machines. JCSS was established to ensure the traceability of measurements in line with the provisions set forth in Chapter 8 of the Measurement Act.

It is a system operated by the International Accreditation Japan (IAJapan) of the National Institute of Technology and Evaluation (NITE), for testing and providing accreditation to laboratories calibrating measuring instruments that have the technical competency and traceability to meet the criteria for ISO/IEC 17025 (JIS Q 17025) international standards for calibration laboratories.

Tosei Engineering can provide ordinary calibration services and JCSS calibration for coordinate measuring machines—a calibration certificate with the JCSS accreditation symbol is issued after performing JCSS calibrations. A JCSS calibration Certificate guarantees to the public that calibration results are traceable to National Measurement Standards of Japan. With a JCSS calibration Certificate, there is no need to confirm traceability back to upper-level international or national measurement standards. Normal calibration certificates for Tosei Engineering's products and Carl Zeiss series products guarantee that standardized calibration processes are used that can be traced back to standard instruments via the traceability chart. JCSS calibration, however, provides more confident evidence as third party accreditation bodies periodically assess whether or not the procedures meet the requirements of ISO/IEC 17025.

Coordinate measuring machines

Tokyo Seimitsu Co., Ltd. is accredited under the Japan Calibration Service System (JCSS) that uses ISO/IEC 17025 (JIS Q 17025) as the accreditation standard and ISO/IEC 17011 as the accreditation scheme. The accreditation agency (IAJapan) that operates JCSS is a signatory to the mutual recognition arrangements with the Asia Pacific Accreditation Cooperation (APAC) and the International Laboratory Accreditation Cooperation (ILAC). Tokyo Seimitsu Co., Ltd. is an international MRA-compliant JCSS accredited laboratory. The accreditation number is JCSS 0047.

Tosei Engineering Corp. is accredited under the Japan Calibration Service System (JCSS) that uses ISO/IEC 17025 (JIS Q 17025) as the accreditation standard and ISO/IEC 17011 as the accreditation scheme. The accreditation agency (IAJapan) that operates JCSS is a signatory to the mutual recognition arrangements with the Asia Pacific Accreditation Cooperation (APAC) and the International Laboratory Accreditation Cooperation (ILAC). Tosei Engineering Corp. is an international MRA-compliant JCSS accredited laboratory. The accreditation number is JCSS 0198.

Certain surface texture measuring instruments and reference specimens

Tokyo Seimitsu Co., Ltd. is accredited under the Japan Calibration Service System (JCSS) that uses ISO/IEC 17025 (JIS Q 17025) as the accreditation standard and ISO/IEC 17011 as the accreditation scheme. The accreditation agency (IAJapan) that operates JCSS is a signatory to the mutual recognition arrangements with the Asia Pacific Accreditation Cooperation (APAC) and the International Laboratory Accreditation Cooperation (ILAC). Tokyo Seimitsu Co., Ltd. is an international MRA-compliant JCSS accredited laboratory. The accreditation number is JCSS 0047.

Tosei Engineering Corp. is accredited under the Japan Calibration Service System (JCSS) that uses ISO/IEC 17025 (JIS Q 17025) as the accreditation standard and ISO/IEC 17011 as the accreditation scheme. The accreditation agency (IAJapan) that operates JCSS is a signatory to the mutual recognition arrangements with the Asia Pacific Accreditation Cooperation (APAC) and the International Laboratory Accreditation Cooperation (ILAC). Tosei Engineering Corp. is an international MRA-compliant JCSS accredited laboratory. The accreditation number is JCSS 0198.

Inspection details