In today’s world, there are heightened demands relating to cost and quality due to intensified global competition, but there is also a need to respond to labor shortages and diverse work styles. The key to solving these conflicting issues is the streamlining of manufacturing processes. ACCRETECH’s automation/labor-saving measurement solutions contribute to the streamlining of our customers’ manufacturing from the aspect of measuring instruments.

ACCRETECH’s Automation/Labor-saving Measurement Solutions

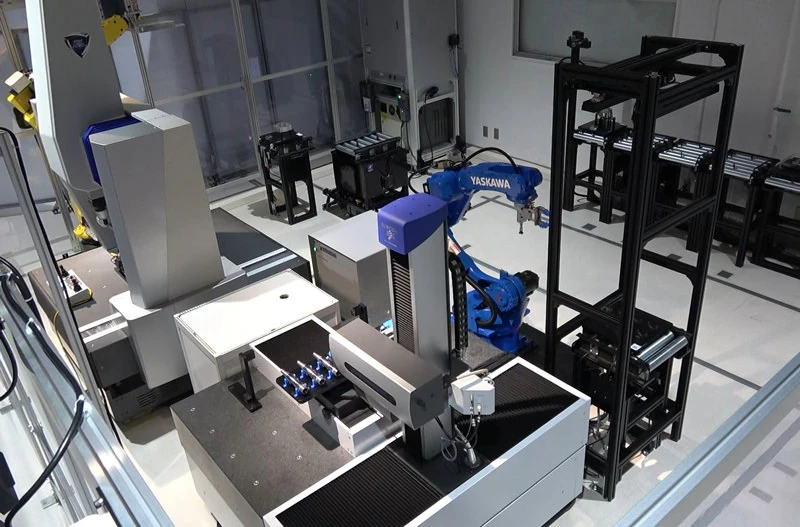

From Labor-saving with Automatic Workpiece Changeover to Construction of Fully-Automated/Unmanned Inspection Cells

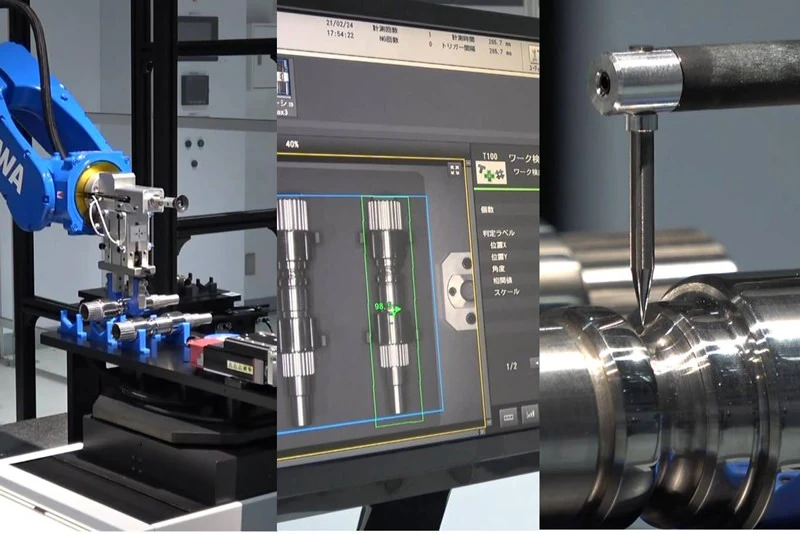

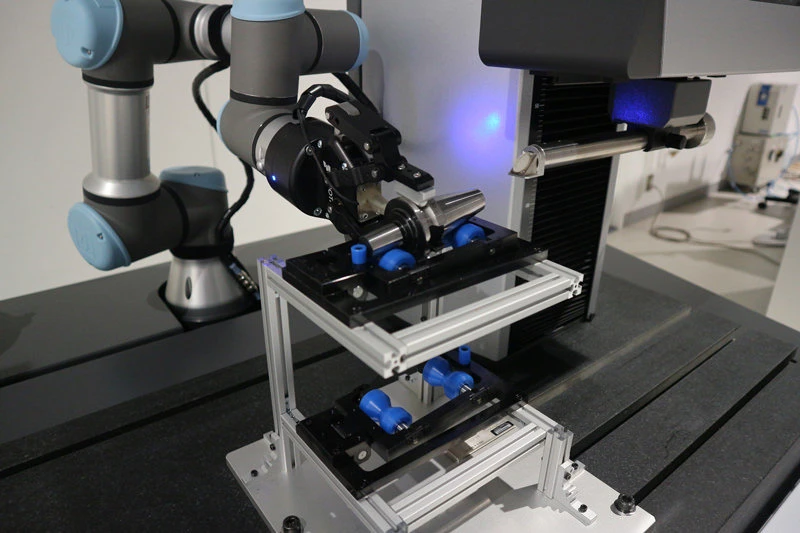

ACCRETECH offers solutions to partially or fully automate inspection processes by linking our CMMs and other measuring instruments to peripheral equipment such as industrial robots, cobots, AGVs (automatic guided vehicles), and image recognition sensors. Substituting human operators for robots and AGVs in processes conventionally performed manually, such as workpiece changeover/transfer and measuring program start-up, has dramatically streamlined these processes. Of course, ACCRETECH’s automation and labor-saving measurement solutions are not only applicable to newly-installed measuring instruments. Even existing measuring instruments* can be reborn as automated/labor-saving systems by performing the necessary modifications and linking with robots, etc.

Please consult our sales representative regarding the feasibility of this option.

Abundant Benefits In Addition to Inspection Process Streamlining

Cost reduction and response to labor shortages: Establishes inspection systems with minimal personnel

Release from simple work: Alleviates burden on workers and creates opportunity for a step-up from simple tasks to high-added-value work

High-reliability quality assurance: Minimizes variation in manually-measured data while preventing defective parts through efficient 100% inspection

Greater production capacity: In addition to improving inspection efficiency, automation enables unmanned inspection at night, thus preventing inspection from becoming the production bottleneck and ultimately increasing production volume

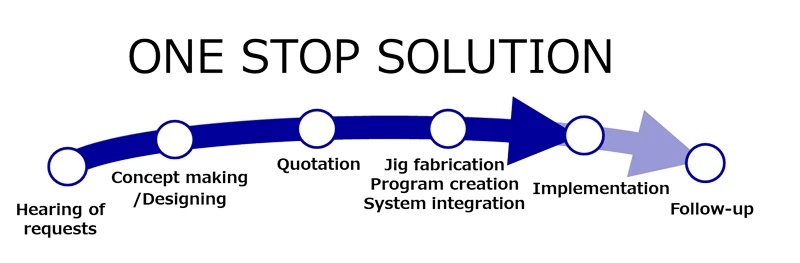

ONE STOP SOLUTION – ACCRETECH provides a comprehensive service, including communication with manufacturers of robots and other transfer equipment and system integrators, as well as fabrication of necessary jigs

The greatest feature of ACCRETECH’s automation and labor-saving measuring solutions is that ACCRETECH Group oversees the entire service package, from listening to customers’ requests, planning, design, quotation, and system introduction, to after-sales support. Naturally, our planning, design, and quotation services are not for the measuring instrument alone but rather the entire system integrating all essential elements, such as robots, AGVs (automatic guided vehicles), jigs, and programs. Customers don’t need to worry about all the preparations prior to introduction.

Examples of Automation and Labor-saving Measurement Solution Packages

Basic

…Ready-made package recommended for first-time automation and robot introduction

E.g.) Automatic changeover and continuous measurement of a fixed number of workpieces loaded in a stocker

Surface texture and contour integrated measuring instrument + cobot + ready-made workpiece stocker

Advanced

…A package enabling linkage with other devices and measurement of multiple workpiece types

E.g.) Scans workpiece information using a QR code, automatically selects corresponding measurement plan, then measures workpiece

Multi-sensor measuring machine + cobot or industrial robot + semi-custom made workpiece stocker + QR code reader

Full-Custom

…Fully-automated/unmanned inspection cells to meet customer requests

E.g.) Fully-automated/unmanned inspection consisting of multiple measuring machines that receive workpieces from other processes via a loader

CMM + Surface texture and contour integrated measuring instrument+ industrial robot + workpiece loader+ QR code reader + AGV