Machine tools are indispensable for manufacturing that makes our lives comfortable and convenient. In order to manufacture products of various Profile accurately and efficiently, machine tools must have high precision, high speed, and high rigidity. As such, a machine tool’s components must be of extremely high quality. ACCRETECH proposes a variety of measurement solutions related to machine tools, from high-precision measurement of components to comprehensive inspection of machine tools themselves, dimensional management of workpieces during machining using machine tools, and abnormality detection.

Improving Machine Tool Quality From The Component Level

-Higher-precision measurement of the spindle, said to be the core of a machine tool-

Spindles are one of the most important components of machine tools that require high precision, high speed, and high rigidity. Since spindles need to rotate with high precision at a speed of tens of thousands of revolutions and bear the brunt of the machining load, managing geometric tolerances such as roundness, cylindricality, and coaxiality is critical. In order to strictly manage these geometric tolerances, it is necessary to have a roundness and cylindrical profile measuring instrument that is even more precise than a CMM.

Labor-saving inspection process to maintain high accuracy

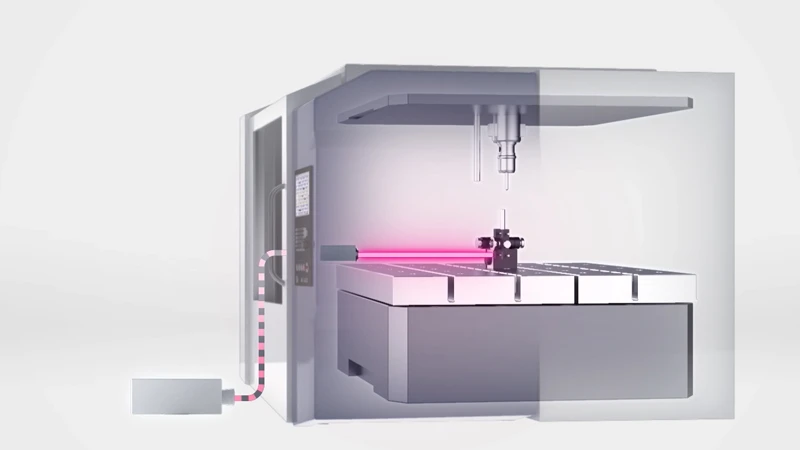

- Accurate correction of pitch error in machine tools -

In order to machine complex workpieces with high precision, it is necessary to ensure that the positioning of each axis can be performed with extreme accuracy. This requires the measurement of each axis using a laser interferometer and NC error correction. DISTAX, ACCRETECH's laser interferometer with optical fiber, not only alleviates the hassle of setup with a unique method of connecting the laser light source and interferometer with optical fiber, but also allows measurement of X, Y, and Z axes with one reflector setting. In addition, it supports inspections and the output of inspection results in accordance with ISO 230-2 (1988 and 2014), which is indispensable for managing the trade of machine tools used outside Japan. Please try DISTAX, which saves labor in positioning accuracy inspection of machine tools and realizes high-precision machining.

Preventing Defective Products Due to Poor Processing

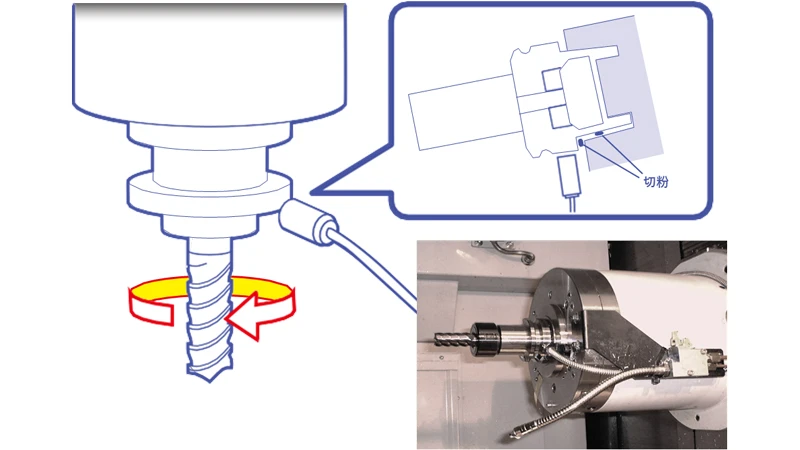

-Non-contact, high-precision, and high-speed measurement of tool run-out-

Machine tools use the tools they are equipped with to machine workpieces made from metal and other materials, and it is important that the tools are properly installed to enable stable high-precision machining. The ATC Run-out Detection System, developed by ACCRETECH in 2002, uses an eddy-current sensor to measure run-out down to 3 μm of mounted tools. The measurement is done with no contact with high precision and at a high speed to detect tool run-out caused by bearing failure or chips stuck in the tapered part of the tool, in order to prevent sudden workpiece machining failure. By simply incorporating the ATC Run-out Detection System into a machine tool, it is possible to avoid a mass occurrence of defective products due to not noticing intrusive chips, as well as 100% inspection of workpieces in order to identify defective products, thus cutting down on unnecessary labor. ACCRETECH can help you improve your productivity through measurement solutions for tools mounted on machine tools.