Medical devices are machines and equipment that are used to diagnose, treat, or prevent diseases in humans or animals, or that are intended to affect the structure and function of the body. ACCRETECH will propose the best solution for potentially life-saving medical devices in the measurement process from the development to the production of high-quality products that demand high safety and reliability and guarantee traceability.

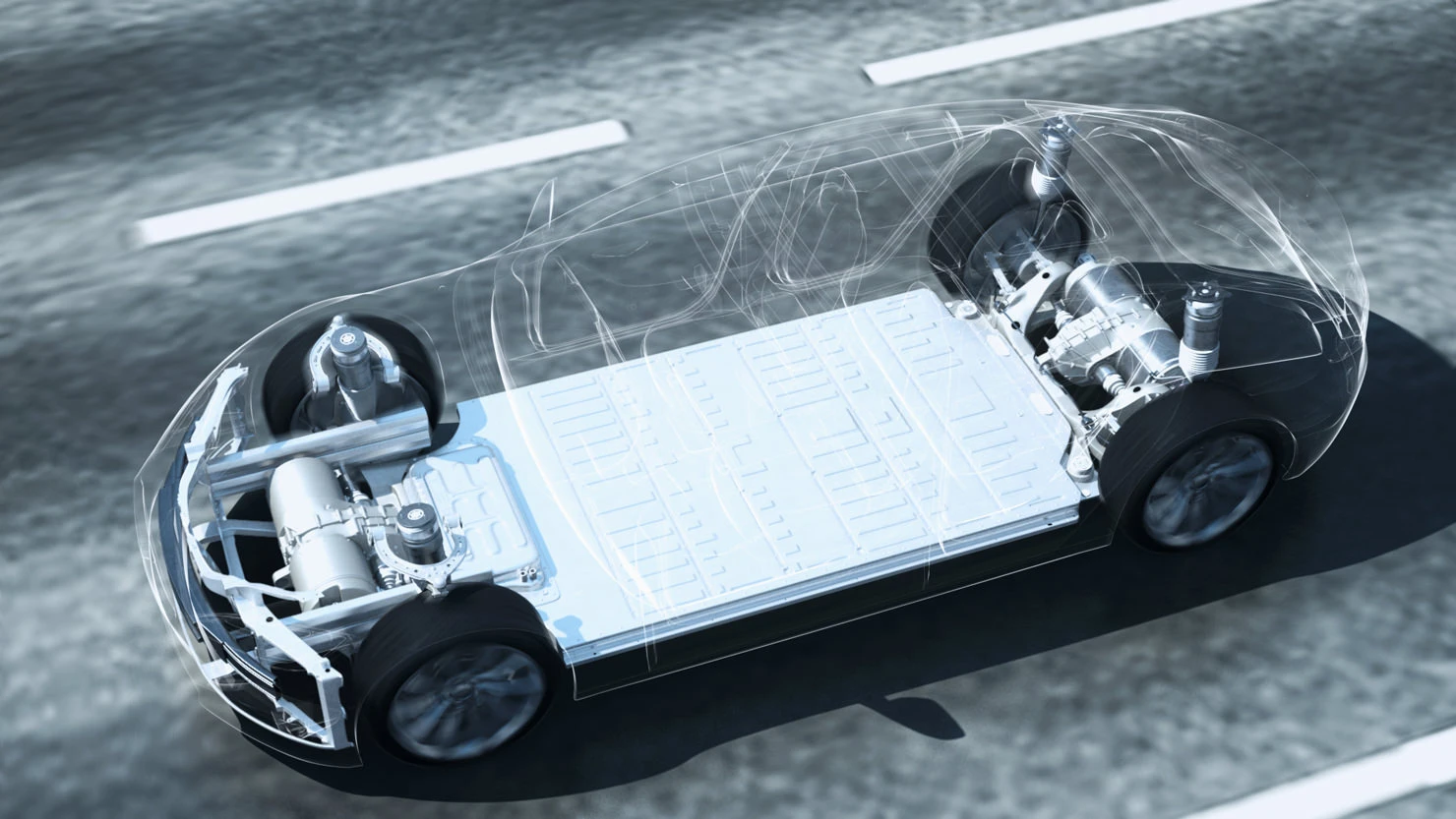

Managing the Mirror and Freeform Surfaces of Artificial Joints

The demand for artificial joints to treat lower limb joint diseases, which reduces activity in the elderly, is growing worldwide. Artificial joints are embedded in a patient’s body to replace joint functions, and two typical examples are artificial hip joints and knee joints. The artificial knee joint consists of a freeform surface similar to a biological joint with a sliding part shape to reproduce complex motion with high joint freedom. In order to manage this freeform surface, it is necessary to measure lines or surfaces by scanning with a non-contact sensor, rather than point measurement using a contact probe of a regular CMM. ACCRETECH proposes ZEISS Dotscan, a chromatic white light sensor for CMMs, as a solution achieving non-contact, ultra-high-speed measurement of mirror and freeform surfaces, such as femoral components of artificial knee joints.

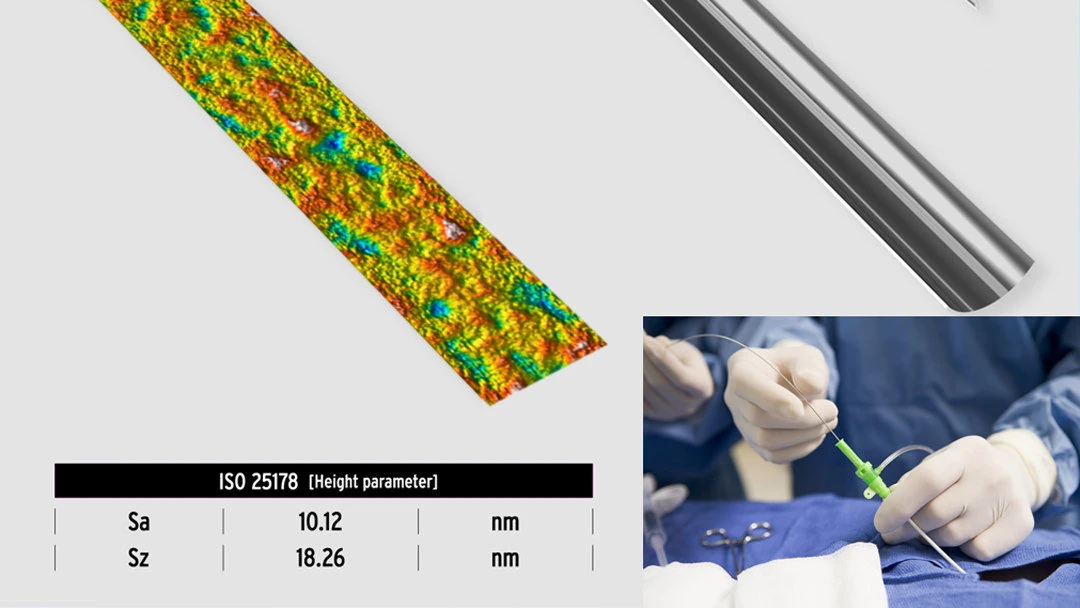

Managing slidability of the catheter surface

Catheters are thin, flexible tubes inserted into the body of a patient undergoing tests or treatment. They are categorized as a surgical device of medical devices for treatment. There are many types of catheters and among these, catheters for performing angiography and endovascular treatment are known as intravenous catheters. Many intravenous catheters are given a special coating to smooth the surface and prevent poor slidability due to friction with fatty tissue when passing through the vascular wall. Opt-scope, a white-light interference microscope capable of non-contact measurement of surface roughness at the nano-level, is the optimal device to manage the surface properties of intravenous catheters.

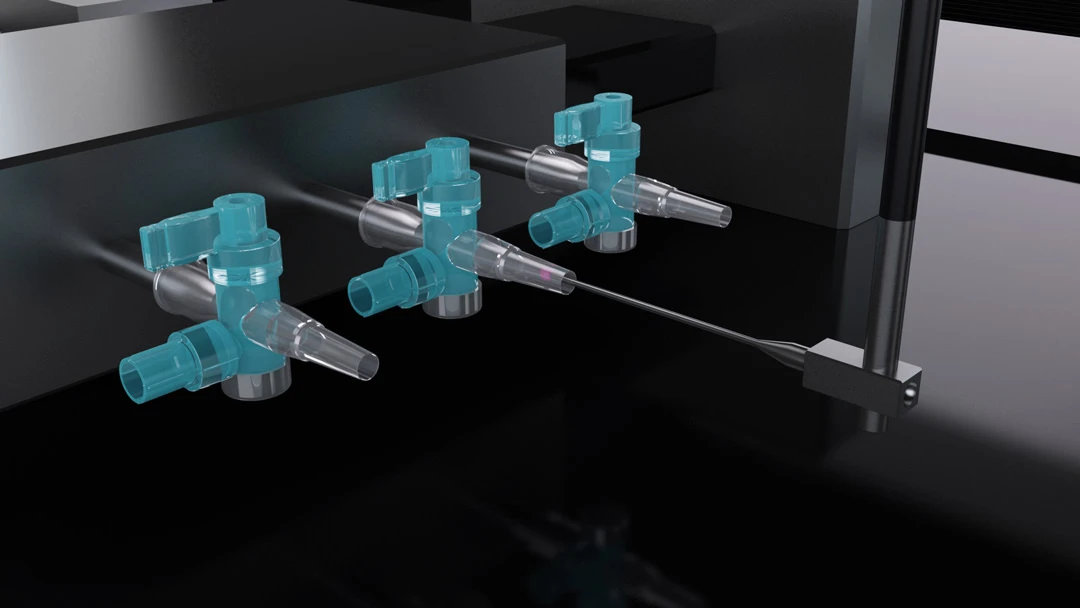

Preventing accidents in the blood circuit

With the blood circuit used for hemodialysis, etc., there is a risk of accidents such as blood leaks and air intake due to problems with the connecting portions of components comprising the circuit. Some factors to such accidents may be the connecting portion between the tube and 3-way stopcock, and connecting portion between the circuit and syringes used for blood sampling and filler replacement fluid. Quality assurance of each connecting portion by dimensional inspection is essential for the prevention of such accidents. ACCRETECH proposes a number of solutions for more reliable quality assurance, including ZEISS O-INSPECT - multi-sensor measuring equipment performing image dimension, contour, and 3D measurement in a single unit, and ZEISS METROTOM – equipment capable of nondestructive measurement of both a component’s surface and interior at the same time.