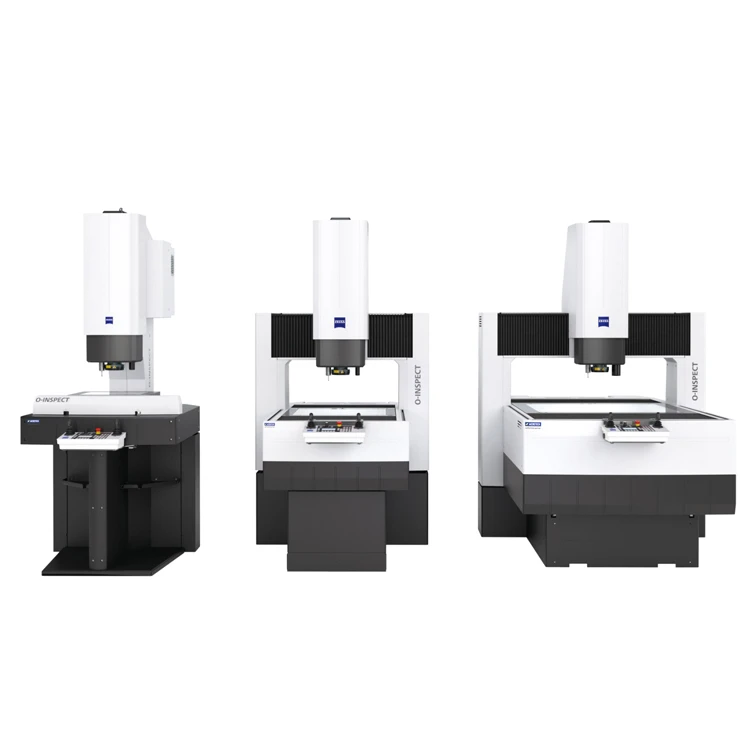

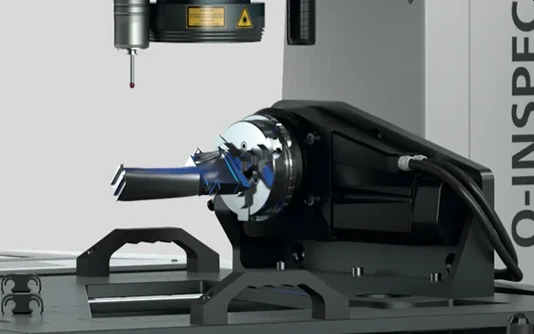

ZEISS O-INSPECT

A multi-sensor measuring machine equipped with contact and non-contact type sensors

Features

ZEISS O-INSPECT is a multi-sensor measuring machine equipped with contact and non-contact type sensors.

It is equipped with high-accuracy contact scanning sensor VAST XXT and high-accuracy non-contact image sensor Discovery. V12 as standard features.Moreover, non-contact measurement of three-dimensional microstructures can be performed with white light distance sensor ZEISS DotScan.This is an all-in-one measuring machine developed by merging the highly-reputed measurement technology of the industrial measuring machine division and the outstanding optical technology of the microscope division of ZEISS.

Thrills of measuring with ZEISS lens.

Telecentric Zoom lens Discovery. V12

The standard equipment Discovery.V12 is capable of high precision image measurements of workpieces made from a variety of materials. It achieves results with a high reproducibility due to the switchable 10-stage zoom lens. In addition, it can be used as a telecentric lens for major magnifications, and measures dimensions accurately without depending on the distance from the object.

Long working distance for all magnifications

The operating distance achieves a long distance of 87 mm for all magnifications. It ensures a safe distance from the object to be measured, and it handles measurement locations with deep steps.

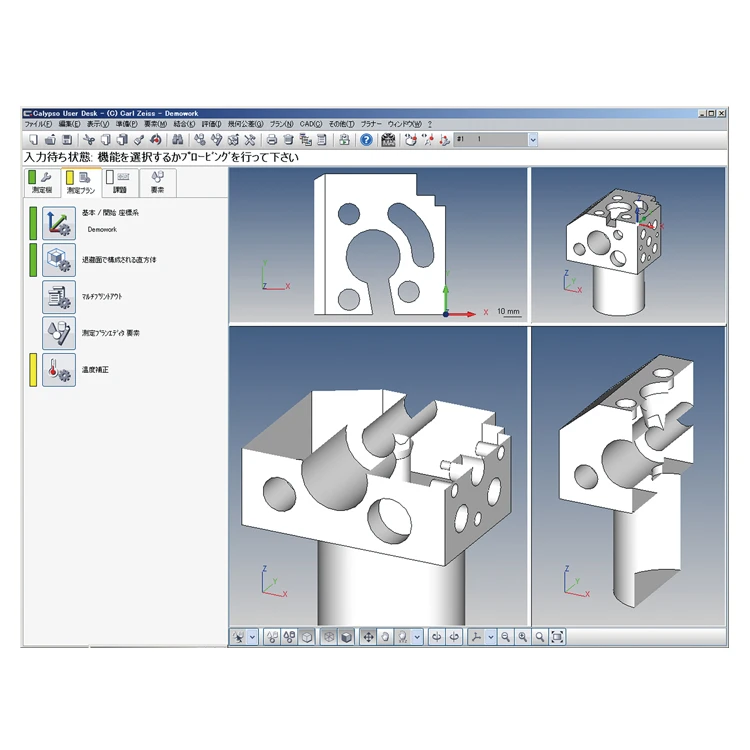

Enabling automatic illumination settings*

Due to the automatic lighting settings with maximum contrast, it detects the optimal edge. Lighting settings obtained are saved and by using them for the second measurement and after, variation due to differences in lighting settings is suppressed, and homogeneous measurement results are obtained.

*It requires the CALYPSO2016 or later (aligned to the right like the current page)

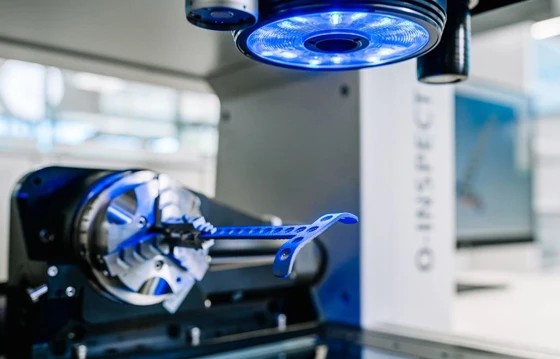

Uniform recognition of edges on glossy surfaces

The ring light is equipped with a Fresnel lens cover, which reduces uneven reflection of lighting during measurement. Even if the measurement location is a glossy surface, it clearly recognizes the edge.

Contact type Scanning Probe VAST XXT

ZEISS O-INSPECT is equipped with contact scanning probe VAST XXT as a standard feature.

Enabling high-accuracy scanning measurement

VAST XXT enables measurement of deep holes, side surfaces of workpieces, oblique holes, etc., which are difficult to measure with image sensor.With the scanning measurement function, in addition to single point measurement, profiles can be captured accurately.

Wide range of accuracy guarantee temperatures

In contact measurement, accuracy is guaranteed in a wide temperature range of 18℃ to 30℃.

White light distance sensor ZEISS DotScan capable of non-contact high-speed measurement of diverse workpieces (optional)

ZEISS DotScan is a white light distance sensor based on the confocal principle.It achieves non-contact measurement of a wide variety of workpieces (10/3/1 mm), such as three-dimensional microstructures, transparent parts including glasses and lenses, soft parts that are deformed by contact measurement, glossy polished surfaces, etc.The sensor can be selected from three kinds of sensors with different measuring ranges, and sensors of another measuring range can be retrofitted.

Able to measure thickness of transparent parts and profile of underlying surfaces after coating

Multiple peaks can be detected and able to measure a surface profile, film thickness of transparent workpieces, and thickness of clear coatings.

Optimal for measurement of micro profiles and edges (radius correction is not required)

Small spot diameter, which is φ8 μm at a minimum (1mm measuring range type), enables accurate measurement of microstructure and minute edge profiles.

High-accuracy non-contact measurement of mirror surface workpieces without spraying

Workpieces with highly glossy surfaces like mirror surface can be measured as they are without spraying.

Non-contact, ultra-high-speed flatness measurement of flat workpieces

Flat workpieces were previously subjected to point measurement for flatness evaluation to avoid the impact on surfaces, but with ZEISS DotScan, measurement time can be significantly reduced by non-contact, ultra-high-speed measurement.

New feature! Greatly reduced measurement time with the ZVp (ZEISS VAST probing)

In the contact type ZEISS VAST probing mode, high speed single-point probing is possible, and the measurement time can be greatly reduced in response to the measurement task or the number of single points to be measured. In addition, in the optical ZEISS VAST probing mode, the speed to match the imaging position is increased, and it contributes to the large reduction in the measurement time.

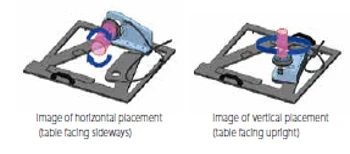

A new rotary table that handles 4-axis scanning (option only for 543/863)

The usage of the optional dedicated rotary table adds a program-controlled rotation axis to the three axes of X, Y and Z of the ZEISS O-INSPECT, drastically improving measurement efficiency.

Can be placed both horizontally and vertically

Horizontal placement of the rotary table (facing sideways) enables contact and non-contact measurement of workpieces in all directions.Vertical placement of the rotary table (facing upright) enables high-accuracy scanning measurement of gears and cylindrical workpieces using contact sensor.

.webp)