Climate Change

For many years, Tokyo Seimitsu has set its own targets and worked to conserve energy at its production sites, the Hachioji and Tsuchiura plants. In order to achieve the reduction targets required of signatories to the Paris Agreement and the 2030 target for reducing greenhouse gas emissions set by the Japanese government on April 22, 2021, we have set new medium- and long-term reduction targets for CO₂ emissions for energy used and consumed at both plants (Scope 1 and 2), including for business activities, production activities, and research and development. To achieve these targets, we are working to decrease electricity consumption by using electricity derived from renewable and low-carbon sources, and switching to high-efficiency equipment. Results are inspected and evaluated.

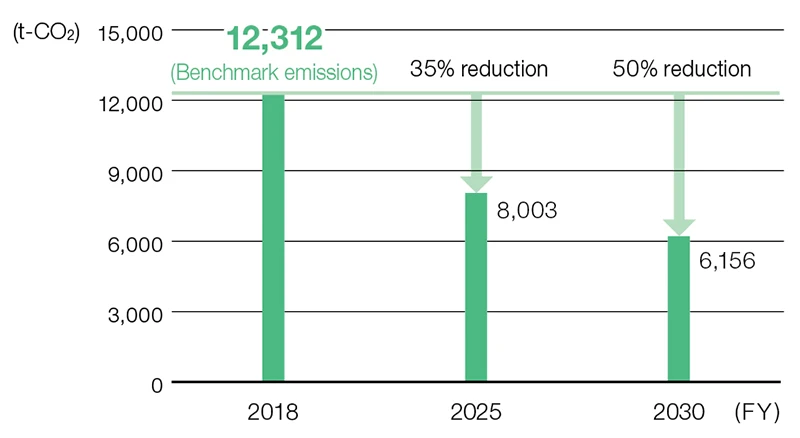

CO₂ Emission Reduction Targets

2025 Target By fiscal 2025, reduce Scope 1*¹ and Scope 2*² emissions by 35% from fiscal 2018*³ levels

2030 Target By fiscal 2030, reduce Scope 1*¹ and Scope 2*² emissions by 50% from fiscal 2018*³ levels

Organizations covered: Tokyo Seimitsu Co., Ltd. Hachioji Plant, Hanno Plant (from July 2023), Tsuchiura Plant, and Furudono Plant (from October 2023)

*¹ Direct GHG emissions by the Company (emissions from fuel combustion, on-site power generation, and industrial processes)

*² Indirect emissions resulting from the use of electricity and heat supplied by other companies (e.g. emissions associated with electricity purchased from electric power companies)

*³ FY2018 standard emissions (Scope 1 + Scope 2): 12,312 (t-CO₂)

CO₂ Emission Reduction Results (FY2024)

| Objectives | Plans/Targets | Result (FY2024) |

| CO₂ Emission Reduction (Scope1+Scope2) |

35% reduction compared to FY2018 by FY2025 Year :2021 Period :FY2020 to FY2025 Benchmark emissions:12,312t-CO₂ Reduction target : 8,003t-CO₂ |

12,733t-CO₂ (3.42% increase compared to fiscal 2018) |

Locations covered: Tokyo Seimitsu Co., Ltd. Hachioji Plant, Hanno Plant, Tsuchiura Plant, and Furudono Plant

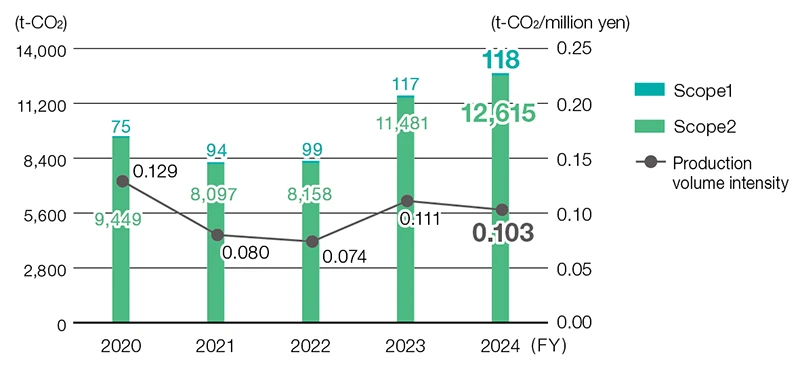

Trend in CO₂ Emissions

| Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |||

| Total CO₂ emissions(Scope1 and Scope2) | t-CO₂ | 9,524 | 8,191 | 8,257 | 11,598 | 12,733 | ||

| Scope1 | t-CO₂ | 75 | 94 | 99 | 117 | 118 | ||

| Gas(LPG) | t-CO₂ | 42 | 51 | 54 | 70 | 71 | ||

| Fuel*1 | t-CO₂ | 33 | 43 | 45 | 47 | 47 | ||

| Scope2 | Electricity | t-CO₂ | 9,449 | 8,097 | 8,158 | 11,481 | 12,615 | |

| CO₂ emissions production volume intensity(Scope1 and Scope2) | t-CO₂ / million yen |

0.129 | 0.080 | 0.074 | 0.111 | 0.103 | ||

Locations covered: Tokyo Seimitsu Co., Ltd. Hachioji Plant, Hanno Plant, Tsuchiura Plant, and Furudono Plant

The results for fiscal 2023 include data from July onward for the Hanno Plant, when construction of the plant was completed, and from October onward for the Furudono Plant to which operations were transferred.

*1 Types of energy covered: Volatile oil, kerosene, and light oil

CO₂ Emissions

Note : The results in fiscal 2023 and later include those of the Hanno and Furudono Plants.

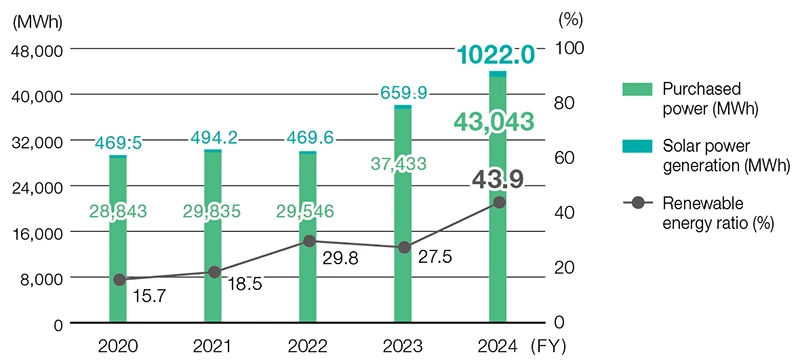

Eco-Factory

Promotion of Global Warming Prevention (Toward a Decarbonized Society)

Almost all the greenhouse gases emitted by the Company are from the CO₂ equivalent of electricity purchased and used during the plant operations. As a global warming prevention measure, we are promoting initiatives focused on the procurement of renewable electricity*¹ and energy conservation.

Specific CO₂ Emission Reduction Examples

Procurement of renewable electric power*¹

Installation/maintenance of solar power generation facilities (Hachioji Plant, Hanno Plant, and Tsuchiura Plant)

Solar Power Generation Facilities Capacity and Amount of Solar Power Generation by Plant

| Plant | Unit | FY2021 | FY2022 | FY2023 | FY2024 | |

| Hachioji | Solar power generation facilities capacity | kW | 406 | 406 | 406 | 406 |

| Amount of solar power generation | MWh | 438.1 | 416.2 | 377.2 | 463.2 | |

| Hanno | Solar power generation facilities capacity | kW | - | - | 713 | 713 |

| Amount of solar power generation | MWh | - | - | 224.6 | 503.5 | |

| Tsuchiura | Solar power generation facilities capacity | kW | 50 | 50 | 50 | 50 |

| Amount of solar power generation | MWh | 56.1 | 53.5 | 58.0 | 55.4 | |

Switchover to low-carbon electricity/CO₂-free electricity*²

|

Hachioji Plant |

: Switched in March 2020 |

*¹ Renewable electric power

Electricity generated from renewable energy sources

*² CO₂-free electricity

Electricity that emits no CO₂ when generated. This refers to electricity that is virtually CO₂-free, utilizing environmental value derived from renewable energy sources that do not emit CO₂

Electricity Use

Locations covered: Tokyo Seimitsu Hachioji Plant, Hanno Plant (from July 2023), Tsuchiura Plant, and Furudono Plant (from October 2023)

Hanno Plant is a newly completed plant, and Furudono Plant is counted as one of the Company plants, with its business operations transferred.

Specific Examples of Efforts to Promote Energy Conservation (Environmental System Program Initiatives)

Upgrade of Machinery (Hachioji Plant)

Upgrade of air conditioning equipment (Tsuchiura Plant)

Introduction of schedule timers (Tsuchiura Plant)

Switchover to LED lighting (Hachioji Plant, Furudono Plant)

Introduction of energy-saving vending machines (Hachioji Plant)

Review of manufacturing process (processing and assembly) (reduction of man-hours)

Capital expenditures related to these initiatives, etc.: Approx. 55 million yen

Management of Environmental Impact on the Atmosphere

The Company manufactures freezers that use HFC* gases, for use in semiconductor manufacturing equipment. We also possess freezers for use in shipping inspections of semiconductor manufacturing equipment. In order to comply with the “Act on Rational Use and Proper Management of Fluorocarbons,” we have a system in place to inspect and maintain freezers, refill and collect fluorocarbons, report on leaks, etc. in an appropriate manner.

* Hydrofluorocarbons (HFCs)

Hydrofluorocarbons do not contain chlorine atoms that deplete the ozone layer and are therefore used as chlorofluorocarbon substitutes in air conditioners and other coolants

Atmospheric Gas Discharge

| Other Gases | Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 |

| CH₄ | t-CO₂ | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| N₂O | t-CO₂ | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| HFC* | t-CO₂ | 189.4 | 61.6 | 19.1 | 65.5 | 111.8 |

| PFC | t-CO₂ | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| SF₆ | t-CO₂ | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

Locations covered: Tokyo Seimitsu Co., Ltd. Hachioji Plant, Hanno Plant (from July 2023), and Tsuchiura Plant

The newly completed Hanno Plant is counted as one of the Company plants.

* As the covered locations and calculation method were changed in fiscal 2024, the data for fiscal 2020 and later were recalculated.

Environment・Society・Governance