Environmental Management

The Tokyo Seimitsu Group contributes to the realization of a sustainable society based on the Group’s Basic Environmental Philosophy, which is “Recognizing environmental conservation as an important theme common to all humankind, Tokyo Seimitsu makes environmental conservation an integral element of all product development, design, manufacturing and service activities.”

Basic Environmental Policy

In all business activities, extending from manufacturing products such as semiconductor manufacturing equipment and precision measuring instruments through the provision of services, everyone at Tokyo Seimitsu must always work with the consideration for “Is this action friendly for the earth?” The goal is to reduce our impact on the earth’s environment to the absolute minimum.

Environmental Policy

1.

We will resolutely drive environmental conservation activities by organizing an environmental management structure having “the Environmental Management Committee” as the top, in which all managers play the key role.

2.

We will comply with environmental laws, ordinances and agreements as well as “the Environmental Policy” and establish voluntary goals to grapple with pollution prevention and environmental conservation.

3.

We will strive to develop and improve environmentally responsible products (products contributing to energy and resource conservation, products that do not use harmful substances).

4.

We will establish environmental objectives for the following items concerning the environmental impacts caused by business activities and improve environmental performance by implementing continuous improvement and reviewing the activities by internal audit.

1) Effective use of natural resources by energy conservation, resource conservation and reduction and recycling of wastes

2) Proper management of harmful substances, reduction in their use and the adoption of replacements

3) Prevention of the global warming through the emission control of the greenhouse gas

5.

We will conduct training programs for all employees to raise awareness of environmental protection. Also, we will ask for the understanding and cooperation of suppliers in environmental conservation.

6.

We will make efforts for environmental conservation activities, including use of sustainable resources, mitigation of climate changes and conservation of biodiversity, through individual business operations, strive to achieve a better global environment and contribute to the development of society.

7.

The environmental management system applies to the activities, products, services and environmental conservation activities of the plants relating to the business activities of Semiconductor Company and Metrology Company.

8.

This environmental policy is disclosed internally and externally.

Three Approaches to Environmental Management

Since obtaining ISO 14001 certification in 1998, we have been promoting initiatives to address environmental issues through approaches that are in line with ISO 14001 policies. Through our products and business activities, we aim to reduce our electricity usage and CO₂ emissions, promote resource conservation, control waste generation and total chemical substance emissions, and contribute to the achievement of a sustainable society.

Eco-Factory

As a manufacturing company, more than 99% of our CO₂ emissions come from the electricity used in our factories, and almost all of the environmental impact (water resources, waste generation, etc.) that we cause is from factory operations. Accordingly, we are promoting activities to reduce environmental impact by primarily focusing on our factories.

Related content

Environmental Management, Climate Change, Resource Recycling and Waste Reduction, Water Resources, and Chemical Substances Control

Eco-Products

In addition to conducting an LCA*¹ as a mandatory task during new product development screening, we also evaluate the environmental impact of conventional products. We have established “eco-products” as products that are developed, manufactured, and improved according to LCAs and promote activities that reduce environmental impact through related to our products.

*¹ Life Cycle Assessment (LCA)

An assessment method that follows calculation standards for converting emissions to CO₂ at every stage from raw material procurement/product manufacturing to disposal

Related content

Environmental Contribution through the Provision of Products

Eco-Mindset

Tokyo Seimitsu has positioned “eco-mindset” as an initiative to raise the environmental awareness of our employees. By actively providing opportunities for employees to participate in social contribution activities in their daily lives and workplaces, such as the introduction of volunteer activities*² in the training of new employees, we contribute to society through our business activities and take action to solve issues.

*² Volunteer activities

Hachioji “Adopt-A-Road Program” activities, Nakanuki Park cleanup activity, eco-partner agreements, etc.

Related content

Social Contribution/Environment and Beautification

Eco-Factory

Environmental Management System

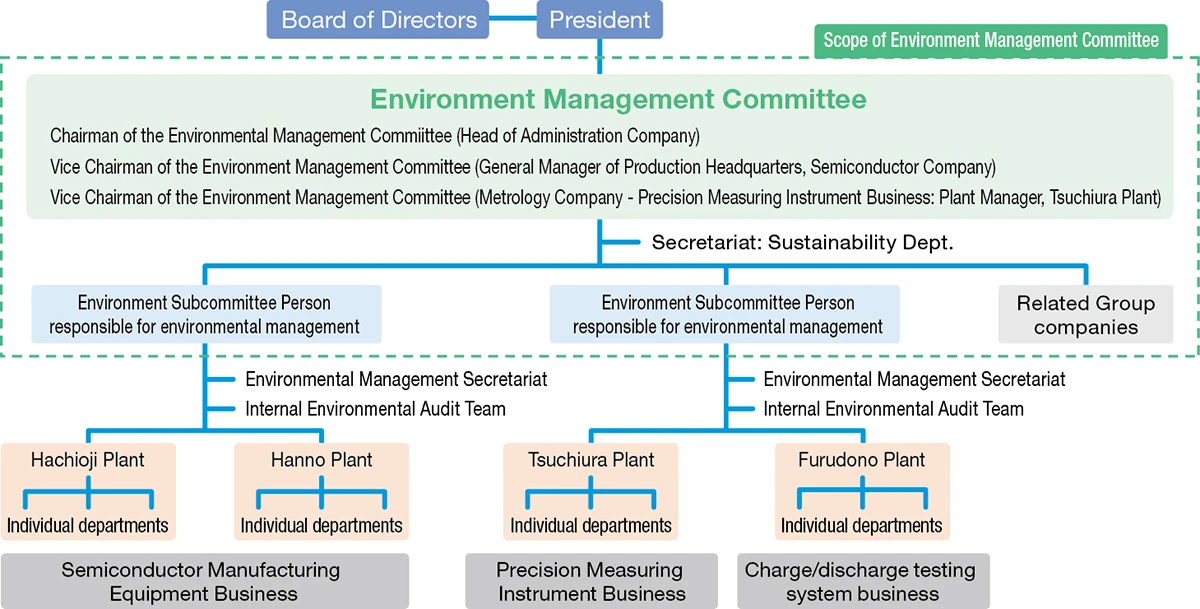

The Company has created an Environmental Management System (EMS) which conforms to ISO 14001. Each Environmental Subcommittee, established as part of the Semiconductor Company and Metrology Company, conducts and evaluates an annual survey of environmental aspects of the organization, products, services, and facilities in accordance with the Environmental Monitoring and Measurement Management Regulations. We prepare, approve, implement, evaluate, and report on our “Environmental Objectives Implementation Plan” and “Environmental Management System Programs” based on legal requirements, our Environmental Policy, and stakeholder requirements.

In addition, while internal audits are conducted twice a year to check the management status of facilities and equipment, the Environment Management Committee confirms that environmental standards are being properly observed, and notifications and reports are appropriately performed. In fiscal 2024, a certification body conducted certification inspections for recertification, including on the Hanno Plant that was completed in July 2023. These inspections have confirmed compliance with the requirements set forth in ISO 14001:2015, including adaptation to climate change (Amendment: February 2024), and that management effectiveness is maintained.

Furthermore, the Furudono Plant, to which some business operations have been transferred from Accretech Powertro System Co., Ltd., maintains its certification status as it was inspected by the same certification body. Going forward, we will seek to have all of our facilities certified, including the Furudono Plant.

Environmental Management Structure

Dissemination of Legal and Environmental Regulatory Information

Each Environmental Subcommittee, established as part of the Semiconductor Company and Metrology Company, delivers legal and environmental regulatory information* from the given company Environmental Secretariat to members of the related Environmental Subcommittee and explains key points. In addition, an environmental internal audit is conducted twice a year to check the laws and regulations that divisions are required to follow as well as level of compliance.

* Main types of legal and environmental regulatory information handled by the Environment Subcommittee: Information on the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof, Industrial Safety and Health Act, Poisonous and Deleterious Substances Control Act, laws related to the Industrial Safety and Health Act, Act on Rationalization of Energy Use and Shift to Non-fossil Energy, Enforcement Order of the Act on Promotion of Global Warming Countermeasures, and trends of the European Commission (F-GAS regulation, etc.), China RoHS, etc.

Environmental Objectives Implementation Plan/Environmental Management System Programs

The divisions affiliated with each Environmental Subcommittee prepare an Environmental Objectives Implementation Plan that specifies the details of efforts, deadlines, and evaluation methods to achieve the environmental targets of the Semiconductor Company and Metrology Company. Based on this plan, they prepare Environmental Management System Programs that provide annual implementation plan and progress information.

The results of the activities based on the Environmental Management System Programs are reported every three months to the heads of relevant divisions and persons responsible for environmental management. In fiscal 2024, we planned programs for 56 items and reached our targets for 53 items, for an overall achievement rate of 94.6%.

Environmental Management System Programs—Fiscal 2024 Activities

Targets : Items Related to Environmental Impact as Defined in Section 4 of the Environmental Policy

1.

Energy conservation (mainly power consumption)

2.

Conservation of resources (mainly water and air)

3.

Reduction and recycling of waste

4.

Reduction of use and finding alternatives for hazardous chemical substances

5.

Reduction in greenhouse gas emissions (mainly power consumption and emissions from company vehicles)

Information on the Programs that Achieved Targets for Fiscal 2024

| Main initiative | Number of programs | Items Related to Environmental Impact as Defined in Section 4 of the Environmental Policy |

| Power reduction due to equipment efficiencies | 25 | 1 |

| Reduction in power consumed during processing and production | 5 | 1 |

|

Power reduction due to improvement proposals and small-group activities |

5 | 1 |

| Reduction in water and air consumption during production | 1 | 2 |

| Reduction in use of organic solvents | 4 | 4 |

| Reduction of hazardous chemical substances | 4 | 4 |

| Reduction of CO₂ through gas substitution | 1 | 5 |

| Reduction in waste | 3 | 3 |

| Others | 8 | 1,5 |

Environment・Society・Governance