Quality

As Tokyo Seimitsu Group products are incorporated into production facilities, we consider outstanding quality as meaning the provision of “stable and reliable product quality” and “prompt and meticulous support quality.” In order to fulfill our responsibility to protect the social status and interests of our Group customers, we are promoting initiatives to improve and upgrade quality and service.

At the Semiconductor Company and Metrology Company, we set quality targets and conduct quality control in line with the quality policy set by our Quality Officer, and work to improve the quality of products and support.

Quality Policy

1.

We comply with laws and regulations in products and production, and contribute to society by prioritizing meeting customer requirements.

2.

At the beginning of every fiscal year, each company reviews its quality targets (priority targets) for the previous year, and sets new quality targets for the new year to enhance product quality.

3.

We continuously improve the performance and effectiveness of our quality management system.

4.

We develop user-friendly products by establishing partnerships with users.

5.

We seek to improve quality through total quality control (TQC).

6.

We seek to improve quality through partnerships with subcontractors.

7.

We enhance customer support in business, technology, and services.

8.

We incorporate safety, quality, and reliability in each production process to achieve stable supply.

9.

The quality management system applies to the activities, products, and services of Semiconductor and Metrology Companies.

10.

This quality policy is disclosed internally and externally.

Target and Result

Customer satisfaction surveys

Target

Achieve a satisfaction rating of 95.0% or more by fiscal 2028

Result

Achieved a satisfactory rating of 94.8% in FY2024

*1 As we achieved the target for fiscal 2025 ahead of schedule, we raised the target from the initially planned 94.8%.

Quality Management Based on ISO 9001

Since obtaining ISO 9001* certification at the Hachioji and Tsuchiura plants in 1994, we have established the Tokyo Seimitsu Quality Management System (QMS) and have been promoting quality improvement activities through the PDCA cycle based on quality policy and quality targets. In fiscal 2024, a certification body conducted certification inspections for surveillance audits, including on the Hanno Plant that was completed in July 2023. These inspections have confirmed compliance with the requirements set forth in ISO 9001:2015, including adaptation to climate change (Amendment: February 2024), and management effectiveness. Furthermore, the charge/discharge testing system business to which some business operations have been transferred from Accretech Powertro System Co., Ltd. since October 2023, maintains its certification status since a special inspection was conducted for the business by the same certification body. Going forward, we will seek to have all of our facilities and business operations certified, including the charge/discharge testing system business.

* ISO 9001:

An international standard concerning systems and mechanisms of management to achieve goals in response to the needs of an organization’s customers and markets, through quality assurance for products and services.

PDCA Cycle Based on Our Quality Policy and Quality Targets

Quality Control Structure

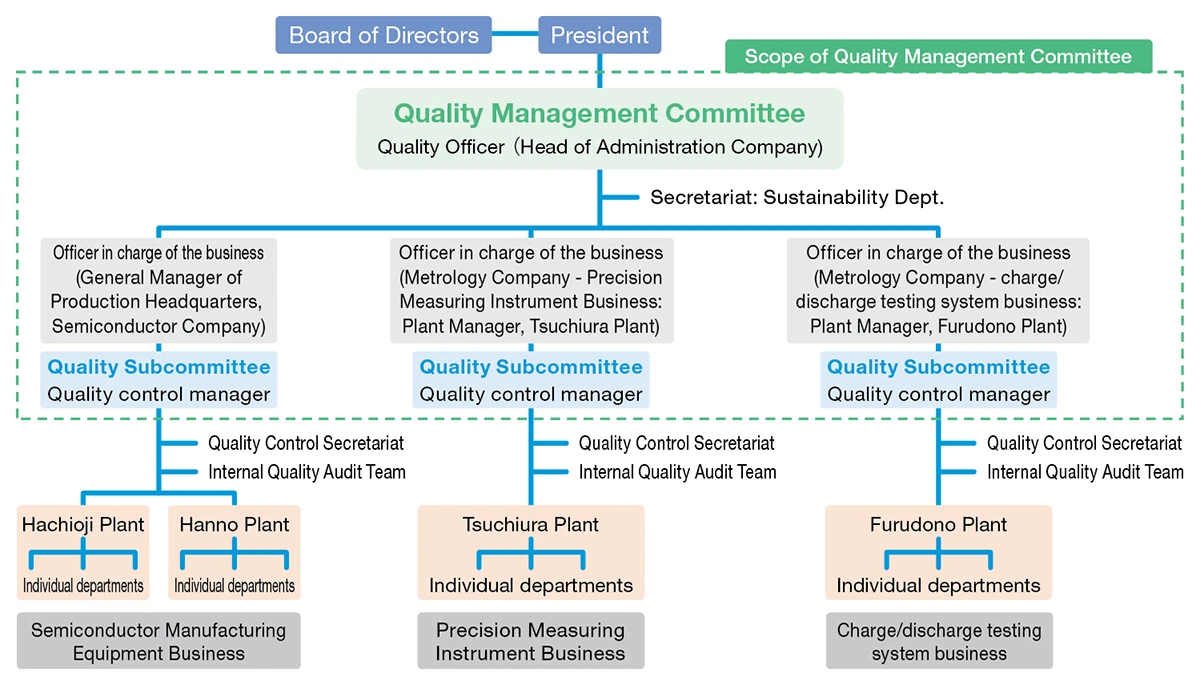

Quality Management Committee

The Quality Management Committee consists of 10 members: One Quality Officer, three officers in charge of business, three quality control managers, and three Sustainability Department members. The Quality Management Committee meets twice a year to review the performance, effectiveness, and appropriateness of the Quality Management System. The Quality Officer reports to the Board of Directors and receives instructions and supervision. In fiscal 2024, there were no quality management issues that required corrective actions to be taken.

Quality Control Structure

Internal Quality Audits

The internal audit team conducts Internal Quality Audits twice a year at the Company. Certified auditors conduct audits in accordance with the quality manual* under the direction of the Quality Control Managers of the Semiconductor Company and Metrology Company, who report the audit results and the effectiveness of the Quality Management System to the Quality Management Committee. During the Internal Quality Audits performed in fiscal 2024, the auditors did not indicate that corrective actions were needed to be taken.

* Quality manual

A manual that defines the procedures for managing Tokyo Seimitsu’s various products and services in accordance with the stipulations of the ISO 9001 standard

Education and Training

The Tokyo Seimitsu Engineering Standards (TES), which are our internal regulations, stipulate quality-related rules, such as certification qualification rules, measuring instrument inspection and calibration standard, and instruction manual creation standard, in addition to production activity-related rules that apply to development, design, manufacturing, production control, quality control, service, and environmental management.

The TES are reviewed once a year and may be established, revised, or abolished as necessary. In each department of the plants, members of the Quality Subcommittee play a pivotal role in providing training to ensure that revised and abolished TES are known throughout the department. The General Affairs Dept. keeps and manages the records of this training.

Number of TES established, revised, and abolished in fiscal 2024

| Established | Revised | Abolished |

| 0 | 8 | 2 |

Supplier Quality Audits

Suppliers who supply many of the parts and components required for our products cooperate in the quality audits that we conduct using our ISO 9001-compliant checklists. In fiscal 2024, supplier quality audits were conducted at 20 companies (cumulative total of 239 companies). There were no follow-up audits conducted as there were no cases of non-compliance with our quality control standards and/or quality requirements.

* Only suppliers who have agreed to check the quality assurance system and implementation status of quality assurance activities

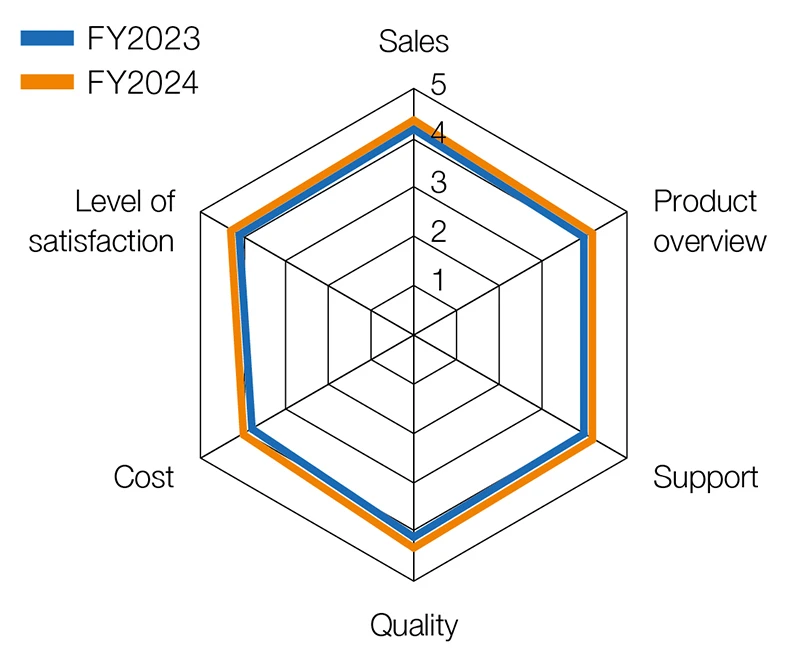

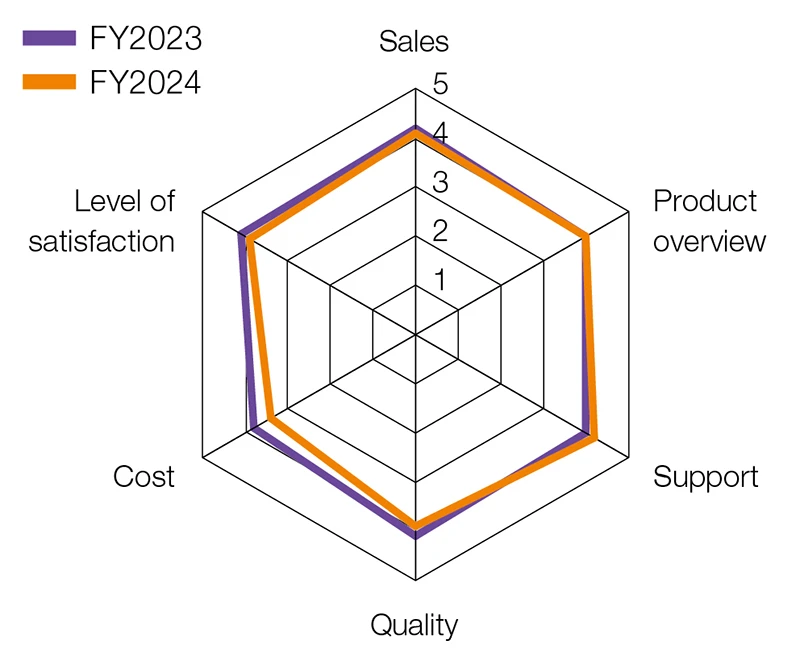

Customer Satisfaction Surveys

To incorporate customer feedback into the improvement and enhancement of our products and services, we conduct customer satisfaction surveys to ascertain customer satisfaction and strive to strengthen it. The percentage of satisfactory ratings in the fiscal 2024 survey was 94.8%, and we are analyzing the results of improvement measures and related factors, and implementing countermeasures needed for improvement.

FY2024 Customer Satisfaction Questionnaire Findings

Semiconductor Manufacturing Equipment Business

Precision Measuring Instrument Business

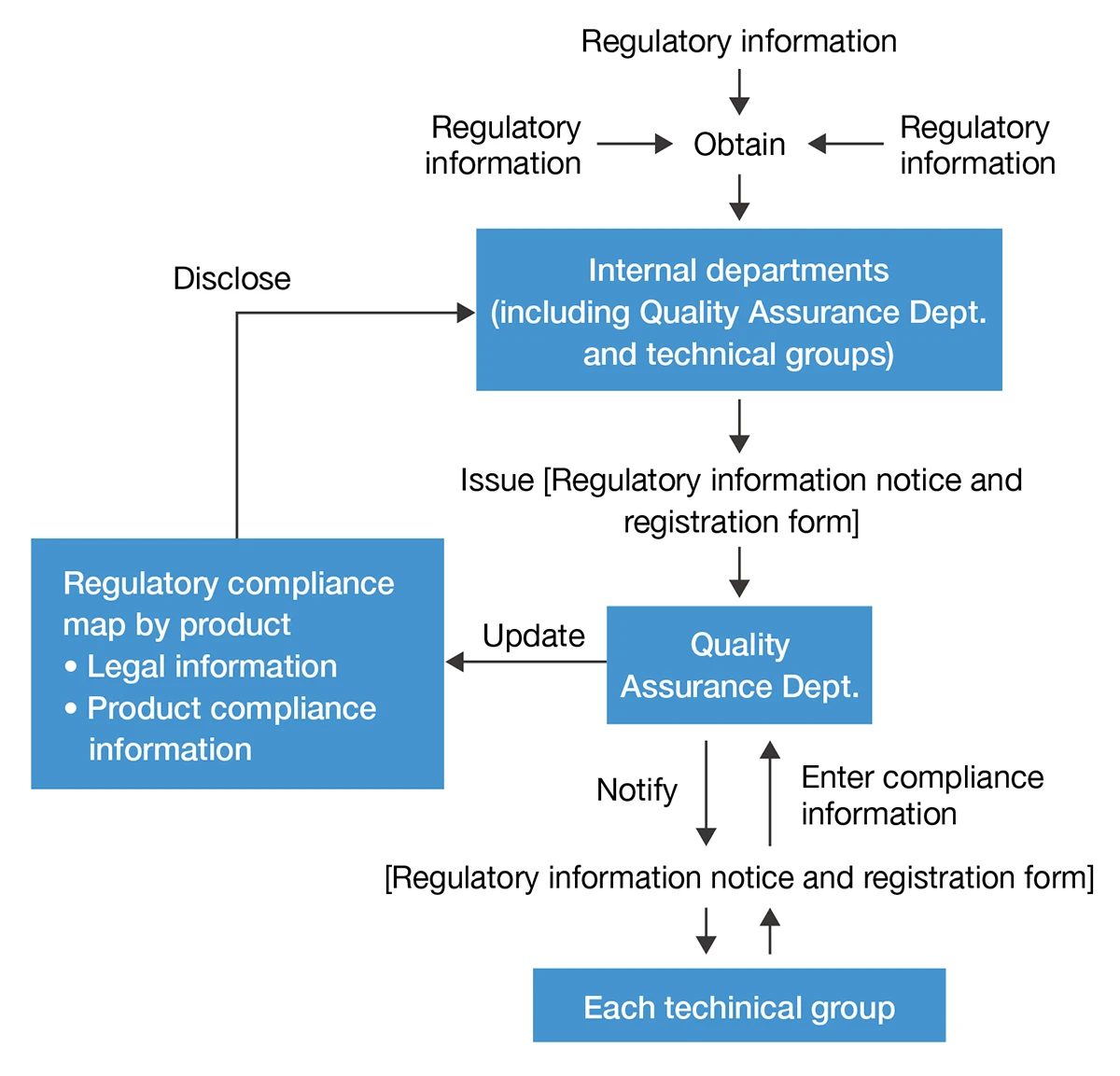

Compliance with Laws Related to Product Quality and Safety

The Quality Assurance Dept. of Semiconductor Company creates a “regulatory compliance map by product” in collaboration with the individual technical groups. This list is used to manage information about the laws and regulations applicable to each product and whether the products comply with those laws and regulations. We have a structure in place that allows us to share regulatory information on a company-wide basis and reflect such information quickly on the products we ship.

Flow of regulatory information management

Environment・Society・Governance