Environmental Contribution through the Provision of Products (Eco-products)

Going forward, we believe it is our role to continue being a responsible manufacturing company that provides safe, high-quality, high-performance, and environmentally friendly products.

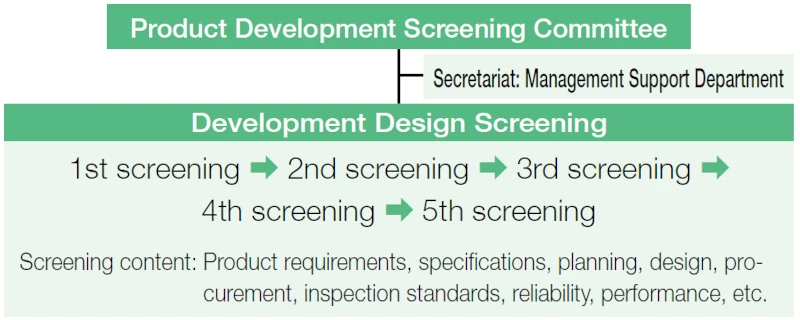

New Product Development Screening

We screen the environmental performance of new products based on our own internal regulations (TES*), and work to develop environmentally friendly products. In accordance with the new product development screening rules, we set up a product development screening committee and conduct deliberations for each product planning theme. The screening rules stipulate principles to be considered during development and design, and include the examination of environmental performance in terms of compactness and minimization of the number of parts, as well as environmental measures.

* TES

The Tokyo Seimitsu Engineering Standards (TES) is a set of binding and enforceable regulations, standards, norms, criteria, and procedures that apply to development, design, manufacturing, production control, quality control, services, and environmental management related to production activities as defined in the Tokyo Seimitsu Regulations (TMR)

New Product Development Screening System

TES New Product Development Screening Rule

| Development Principles |

|

Principles for product development |

| Design Principles |

|

Those related to the environment out of 10 principles ・Minimum number of parts ・Consideration toward product disposal |

Life Cycle Assessment (LCA) during Product Development

The Company recognizes its responsibility for the environmental impacts of its products over their entire life cycles. In 2016, the Technical Working Group of the CSR Committee unified the calculation standards for converting emissions to CO₂ at every stage from product manufacturing to disposal (life cycle assessment: LCA). The CO₂ emissions derived through this method are set as essential evaluation items in new product development screening. LCA targets are set at the time of design, and LCA performance is calculated and evaluated by evaluation organizations to determine the results. Since fiscal 2023, we have been carrying out Life Cycle Assessment (LCA) calculations in a sequential manner for existing products, simulating Scope 3 Category 11 emissions (CO₂ emissions associated with the use of products sold by our company), and evaluating emission reductions resulting from functional improvements. We will continue to make improvements to increase production efficiency and reduce emissions.

Environmentally Friendly Products

Due to the nature of production equipment, products of Tokyo Seimitsu offer many hours of operation and have long service lives. Consequently, when converted into CO₂ emissions, power consumption from usage of products accounts for a good deal of total emissions over the life cycle.

This has prompted us to focus on developing and designing products for reducing environmental impact during manufacturing activities conducted by our customers.

Improvements in equipment performance: Increase in throughput, reduction in the required installation space, reduction in utility consumption, etc.

Provision of solutions: Improvements in technology and processes, data-based optimization, automation, and prediction, etc.

Semiconductor Manufacturing Equipment

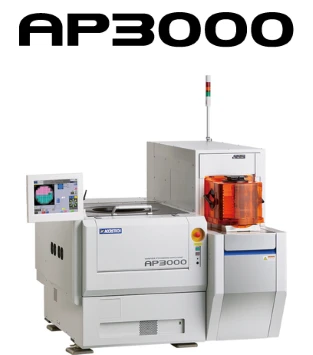

Reducing environmental impact by increasing throughput

Wafer thinning time reduced by approximately 50% (compared to the PG3000RMX)

Lot processing time reduced by approximately 20% (compared to the UF3000EX)

Precision Measuring Instruments

Reducing environmental impact* by proving wide range of guaranteed temperature accuracy

Reduced environmental impact by installing power-saving PC

* Environmental impact caused by precision guaranteed over a wide temperature range:

Generally, measuring instruments are guaranteed to be accurate at an environment of 20℃, but by setting this to a wide range of guaranteed temperature accuracy, the power required for air conditioning can be reduced

Supporting the Manufacture of Power Semiconductors, Devices that Contribute to Decarbonization

Power semiconductors are important devices used in power converters. They are essential devices for the realization of a decarbonized society as they can reduce power consumption and use energy efficiently, and are used in various electronic devices including electric vehicles, railcars, refrigerators, air conditioners, wind power generation equipment, and renewable energy-related equipment.

The Group has strengthened its product lineup to support next-generation power semiconductors that can withstand high voltages and high currents, lose little energy, and be miniaturized.

Lineup of Products that Support Next-Generation Power Semiconductor Manufacturing

Capable of grinding hard, brittle materials such as SiC/GaN substrates

HRG200X / HRG300

High rigid grinders

Options to support high voltages and high currents for SiC/GaN production are available

UF2000

Probing machine

High-pressure, high-speed polishing capabilities improve the polishing rate of SiC wafers

ChaMP-211 / ChaMP-232

CMP (Chemical Mechanical Polishing) devices

Blades available for SiC

Dicing blade

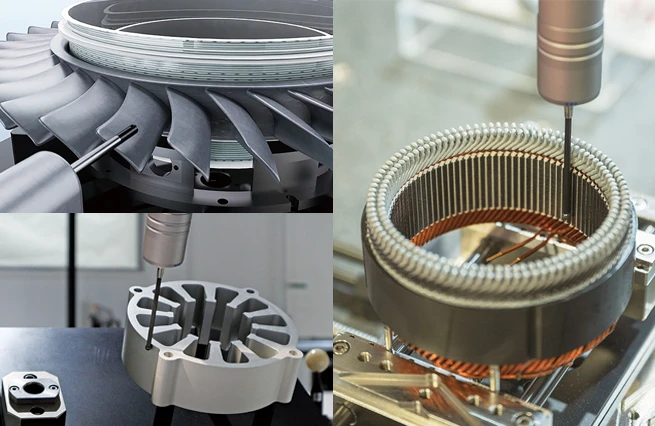

Precision Measuring Instruments that Support Manufacturing Activities Aimed at Decarbonization

In order to efficiently transmit power with precision in automobiles, airplanes, etc., components must be manufactured as designed and as specified. By measuring and managing the dimensions, shape, roundness, and surface texture of parts, manufacturing is progressing toward the realization of decarbonization.

Based on our basic philosophy of “No Measurement, no Manufacturing,” we are contributing to the improvement of performance and fuel efficiency in the automobile and aircraft industries through our measurement technologies.

XYZAX AXCEL Series

Extensive measurement applications Contributes to the improvement of performance

and fuel efficiency in the automobile and aircraft industries through measurement

Evaluating the Safety of Rechargeable Batteries,

Products that Contribute to the Realization of a Sustainable Society

In recent years, climate change brought about by greenhouse gas emissions has become increasingly apparent, and natural disasters have been occurring frequently around the world. In particular, internal combustion engine automobiles and coalfired thermal power generation are cited as generating large amounts of CO₂, and it is said that curbing these emissions is key to saving the global environment. It is important, therefore, that electric vehicles that do not generate CO₂ spread quickly, along with systems that store electricity from solar power generation. Lithium-ion and other rechargeable batteries are at the core of such systems. Our charge/discharge testing systems, which can inspect the charge/discharge performance and life of rechargeable batteries, are used for test batteries during development and inspect batteries during manufacturing, contributing to the development of safer, higher-performance batteries and confirmation of safety and performance in manufacturing.

Charge/Discharge Testing System Lineup

Creating New Value through the Synergy of Semiconductors and Metrology

Tokyo Seimitsu is the only manufacturer of semiconductor manufacturing equipment that possesses measurement technologies. As new value creation unique to our company, we are developing semiconductor manufacturing equipment models with built-in measuring instruments. Equipped with Opt-scope, a 3D white light interferometer microscope that measures surface properties, the relevant model improves the detection accuracy of shape and surface properties, contributing to improved quality and productivity.

Semiconductor Manufacturing Equipment with Built-in Measuring Instrument

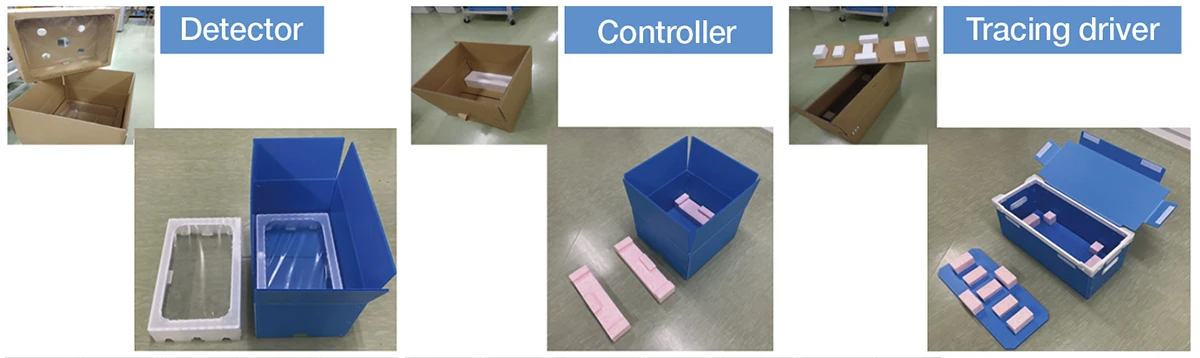

Reduction of Packaging Materials

We have calculated how much waste and how much CO₂ emission we can reduce a year by adopting returnable packaging. Returnable packages are more durable than cardboard boxes. Collecting returnable packages from destinations and reusing the collected packages reduces waste and mitigates the environmental impact. An effort is underway to adopt returnable packaging for SURFCOM NEX.

Environment・Society・Governance